World Precision

According to the problems of Ward Precision project management, the Team has drawn up a set of practical project management plans based on the advanced theory of "dynamic management, real-time sharing" to realize the efficient tracking of progress, cost, resources, performance, risks, etc.

Recently, World Precision Co., Ltd. signed a contract with WisageTech Inc. and launched the  project management system to realize multi-project overall management, improve efficiency, and push the modern management and development of the enterprise to a new level.

project management system to realize multi-project overall management, improve efficiency, and push the modern management and development of the enterprise to a new level.

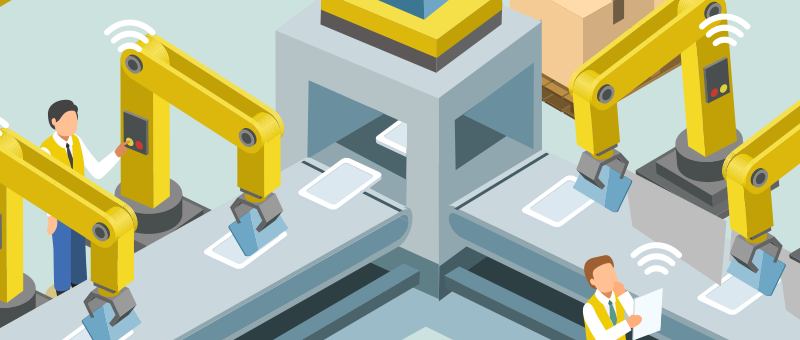

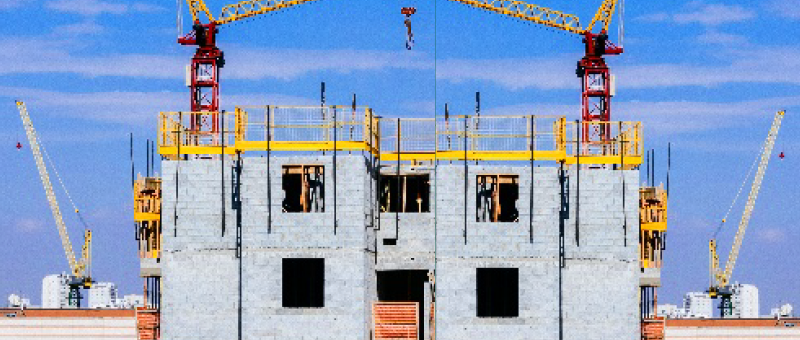

World Precision was established in 2003. It is a large-scale manufacturing enterprise specializing in the design and manufacture of automatic complete machines and the processing of various precision parts. Integrating R&D, manufacturing, assembly, and after-sales service, it has successively established physical factories and after-sales service offices in Zhengzhou, Wuxi, Dongguan, Shenzhen, Shanghai and other places, and established a branch in the United States. Through continuous innovation and research and development, World Precision has continuously expanded its business from the initial Asian market to the global market, from the processing of single precision parts to the field of automatic machine development and production.

World Precision has sufficient precision production and processing equipment, a strict internal quality management system and relatively high quality requirements for products and projects. With the rapid development of the enterprise, its projects are gradually increasing, and the original project management model is difficult to support the current project development needs, leading to the following problems in the project development process:

1. The number of projects increases, making it difficult to coordinate and monitor the progress of projects in a timely manner;

2. Lacking a shared resource platform, it is difficult to share and accumulate the results of the project;

3. Lacking the support of systematic project data, it is difficult to accurately judge and fairly assess the efficiency and performance of R&D personnel;

4. Project data cannot be circulated in a timely and accurate manner, making it difficult to calculate project costs; it is difficult to find problems in the process of project activities timely and make a reminder.

In order to solve the problems encountered in the project management process, World Precision hopes to launch a fully automated project management system to improve the management level of the enterprise and create better economic benefits.

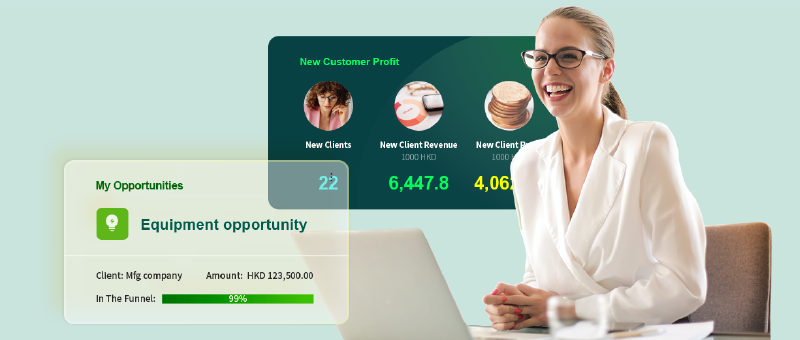

After multiple comparisons, World Precision found that the product explained the core idea of project management very well. It can remind the project participants in time when there is a problem. The application of the mobile phone APP function can enable people outside of the company to know the relevant project information in time, and provide rich functional support in terms of progress, cost, quality, etc. Finally, WisageTech was selected and a cooperation agreement was reached.

product explained the core idea of project management very well. It can remind the project participants in time when there is a problem. The application of the mobile phone APP function can enable people outside of the company to know the relevant project information in time, and provide rich functional support in terms of progress, cost, quality, etc. Finally, WisageTech was selected and a cooperation agreement was reached.

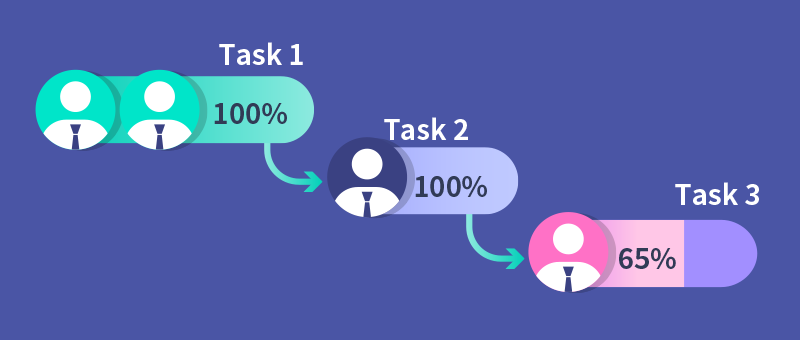

According to the problems of Ward Precision project management, the WisageTech Team has drawn up a set of practical project management plans based on the advanced theory of "dynamic management, real-time sharing" to realize the efficient tracking of progress, cost, resources, performance, risks, etc., which has greatly improved its project management capabilities.

1. Mature performance appraisal standards improve employee performance

Performance appraisal can effectively control the work progress of employees and evaluate employees work abilities. provides a variety of performance appraisal modes, which allows World Precision to set up different performance appraisal tables for different departments and positions, formulate a standardized performance appraisal process for each employee, and timely give feedback on the problems existing in the performance appraisal. The system helps the company implement each performance appraisal work so as to improve employee performance and satisfaction.

provides a variety of performance appraisal modes, which allows World Precision to set up different performance appraisal tables for different departments and positions, formulate a standardized performance appraisal process for each employee, and timely give feedback on the problems existing in the performance appraisal. The system helps the company implement each performance appraisal work so as to improve employee performance and satisfaction.

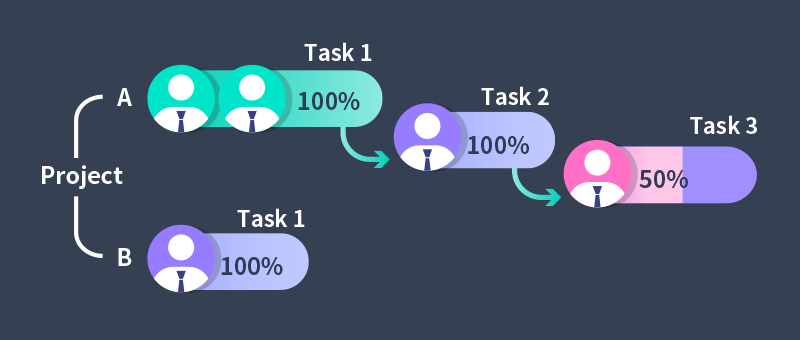

2. Timely project data transmission and overall planning and monitoring of project progress and problems

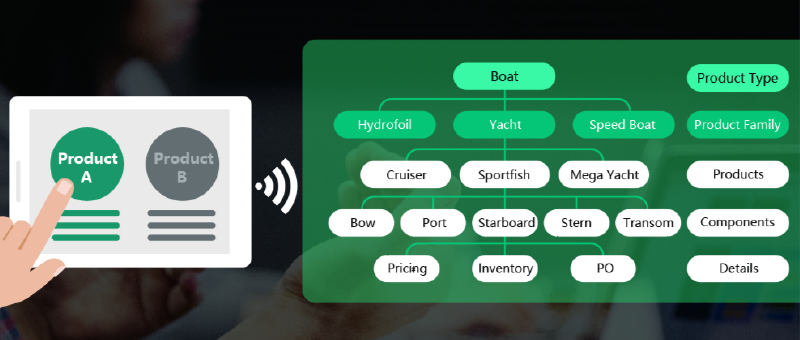

project management system uses WBS structure to drive overall control of project planning and execution, and all data is updated in real time and accurately. The system improves the accuracy and transmission efficiency of project information, allowing the project manager to view the project’s progress and problems with one click. Through the system reminder mechanism, the management of World Precision can timely identify all problems that occur during the project process, adjust the project implementation plan according to the data information, and control the normal operation of the project.

project management system uses WBS structure to drive overall control of project planning and execution, and all data is updated in real time and accurately. The system improves the accuracy and transmission efficiency of project information, allowing the project manager to view the project’s progress and problems with one click. Through the system reminder mechanism, the management of World Precision can timely identify all problems that occur during the project process, adjust the project implementation plan according to the data information, and control the normal operation of the project.

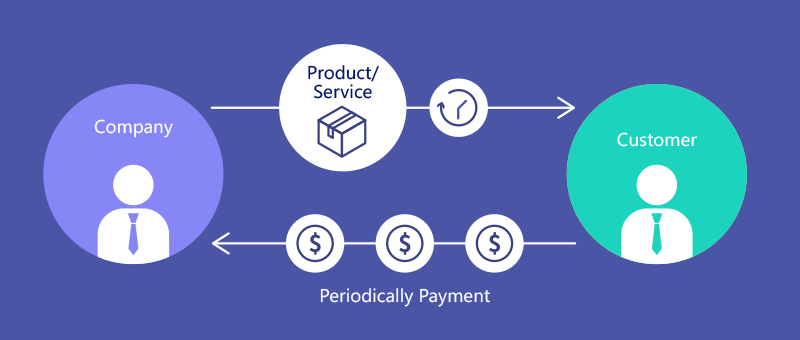

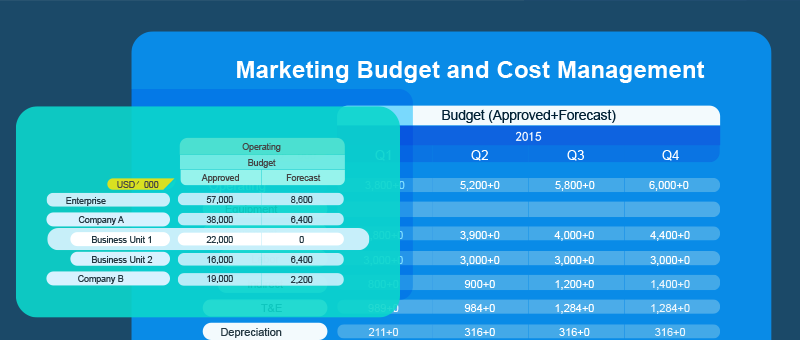

3. Resource and manpower monitoring and allocation, and strict control of project costs

The allocation of project resources and manpower is also an important channel for World Precision to reduce project costs. can not only realize resource allocation and efficiency tracking across departments, sites, and projects, but also can detect the gap between resource skills and needs and improve the matching degree of resources and needs, and resource utilization.

can not only realize resource allocation and efficiency tracking across departments, sites, and projects, but also can detect the gap between resource skills and needs and improve the matching degree of resources and needs, and resource utilization.

4. Follow the progress of the project anytime and anywhere with mobile phones

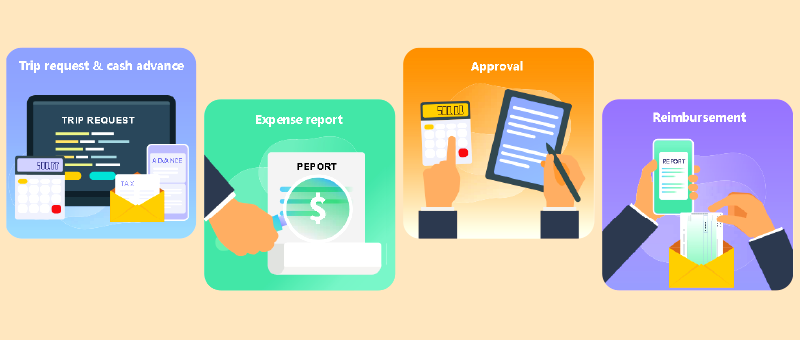

In order to keep track of project progress anytime and anywhere, World Precision has enabled APP, which allows people who are away from the enterprise to instantly view project information, and submit or approve projects. Because the employees can work at any time, work efficiency is improved.

APP, which allows people who are away from the enterprise to instantly view project information, and submit or approve projects. Because the employees can work at any time, work efficiency is improved.

integrates mobile Internet and J2EE technology for real-time connection of enterprise data, which not only realizes efficient automation, but also improves the timeliness and accuracy of data transmission, providing strong support for precise and efficient project management. After more than ten years of operations,

integrates mobile Internet and J2EE technology for real-time connection of enterprise data, which not only realizes efficient automation, but also improves the timeliness and accuracy of data transmission, providing strong support for precise and efficient project management. After more than ten years of operations,  has accumulated rich experience in the field of large-scale R&D and production projects, which will create a new project management environment for World Precision and bring a qualitative improvement to its modern development!

has accumulated rich experience in the field of large-scale R&D and production projects, which will create a new project management environment for World Precision and bring a qualitative improvement to its modern development!

project management system to realize multi-project overall management, improve efficiency, and push the modern management and development of the enterprise to a new level.

project management system to realize multi-project overall management, improve efficiency, and push the modern management and development of the enterprise to a new level.World Precision was established in 2003. It is a large-scale manufacturing enterprise specializing in the design and manufacture of automatic complete machines and the processing of various precision parts. Integrating R&D, manufacturing, assembly, and after-sales service, it has successively established physical factories and after-sales service offices in Zhengzhou, Wuxi, Dongguan, Shenzhen, Shanghai and other places, and established a branch in the United States. Through continuous innovation and research and development, World Precision has continuously expanded its business from the initial Asian market to the global market, from the processing of single precision parts to the field of automatic machine development and production.

World Precision has sufficient precision production and processing equipment, a strict internal quality management system and relatively high quality requirements for products and projects. With the rapid development of the enterprise, its projects are gradually increasing, and the original project management model is difficult to support the current project development needs, leading to the following problems in the project development process:

1. The number of projects increases, making it difficult to coordinate and monitor the progress of projects in a timely manner;

2. Lacking a shared resource platform, it is difficult to share and accumulate the results of the project;

3. Lacking the support of systematic project data, it is difficult to accurately judge and fairly assess the efficiency and performance of R&D personnel;

4. Project data cannot be circulated in a timely and accurate manner, making it difficult to calculate project costs; it is difficult to find problems in the process of project activities timely and make a reminder.

In order to solve the problems encountered in the project management process, World Precision hopes to launch a fully automated project management system to improve the management level of the enterprise and create better economic benefits.

After multiple comparisons, World Precision found that the

product explained the core idea of project management very well. It can remind the project participants in time when there is a problem. The application of the mobile phone APP function can enable people outside of the company to know the relevant project information in time, and provide rich functional support in terms of progress, cost, quality, etc. Finally, WisageTech was selected and a cooperation agreement was reached.

product explained the core idea of project management very well. It can remind the project participants in time when there is a problem. The application of the mobile phone APP function can enable people outside of the company to know the relevant project information in time, and provide rich functional support in terms of progress, cost, quality, etc. Finally, WisageTech was selected and a cooperation agreement was reached.

According to the problems of Ward Precision project management, the WisageTech Team has drawn up a set of practical project management plans based on the advanced theory of "dynamic management, real-time sharing" to realize the efficient tracking of progress, cost, resources, performance, risks, etc., which has greatly improved its project management capabilities.

1. Mature performance appraisal standards improve employee performance

Performance appraisal can effectively control the work progress of employees and evaluate employees work abilities.

provides a variety of performance appraisal modes, which allows World Precision to set up different performance appraisal tables for different departments and positions, formulate a standardized performance appraisal process for each employee, and timely give feedback on the problems existing in the performance appraisal. The system helps the company implement each performance appraisal work so as to improve employee performance and satisfaction.

provides a variety of performance appraisal modes, which allows World Precision to set up different performance appraisal tables for different departments and positions, formulate a standardized performance appraisal process for each employee, and timely give feedback on the problems existing in the performance appraisal. The system helps the company implement each performance appraisal work so as to improve employee performance and satisfaction.2. Timely project data transmission and overall planning and monitoring of project progress and problems

project management system uses WBS structure to drive overall control of project planning and execution, and all data is updated in real time and accurately. The system improves the accuracy and transmission efficiency of project information, allowing the project manager to view the project’s progress and problems with one click. Through the system reminder mechanism, the management of World Precision can timely identify all problems that occur during the project process, adjust the project implementation plan according to the data information, and control the normal operation of the project.

project management system uses WBS structure to drive overall control of project planning and execution, and all data is updated in real time and accurately. The system improves the accuracy and transmission efficiency of project information, allowing the project manager to view the project’s progress and problems with one click. Through the system reminder mechanism, the management of World Precision can timely identify all problems that occur during the project process, adjust the project implementation plan according to the data information, and control the normal operation of the project.3. Resource and manpower monitoring and allocation, and strict control of project costs

The allocation of project resources and manpower is also an important channel for World Precision to reduce project costs.

can not only realize resource allocation and efficiency tracking across departments, sites, and projects, but also can detect the gap between resource skills and needs and improve the matching degree of resources and needs, and resource utilization.

can not only realize resource allocation and efficiency tracking across departments, sites, and projects, but also can detect the gap between resource skills and needs and improve the matching degree of resources and needs, and resource utilization. 4. Follow the progress of the project anytime and anywhere with mobile phones

In order to keep track of project progress anytime and anywhere, World Precision has enabled

APP, which allows people who are away from the enterprise to instantly view project information, and submit or approve projects. Because the employees can work at any time, work efficiency is improved.

APP, which allows people who are away from the enterprise to instantly view project information, and submit or approve projects. Because the employees can work at any time, work efficiency is improved. integrates mobile Internet and J2EE technology for real-time connection of enterprise data, which not only realizes efficient automation, but also improves the timeliness and accuracy of data transmission, providing strong support for precise and efficient project management. After more than ten years of operations,

integrates mobile Internet and J2EE technology for real-time connection of enterprise data, which not only realizes efficient automation, but also improves the timeliness and accuracy of data transmission, providing strong support for precise and efficient project management. After more than ten years of operations,  has accumulated rich experience in the field of large-scale R&D and production projects, which will create a new project management environment for World Precision and bring a qualitative improvement to its modern development!

has accumulated rich experience in the field of large-scale R&D and production projects, which will create a new project management environment for World Precision and bring a qualitative improvement to its modern development!