Project-based Procurement

Challenge

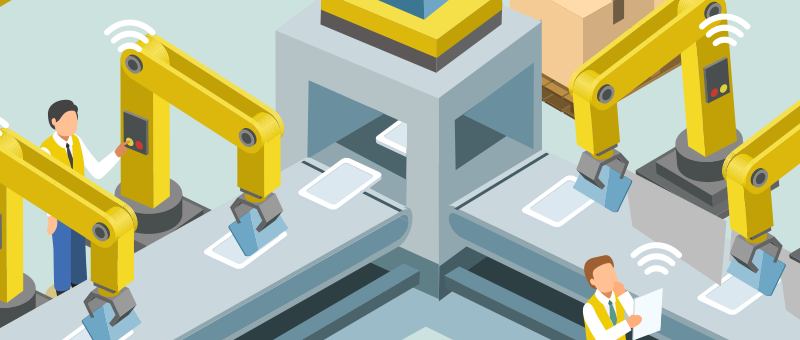

Project-based procurement is typically used when specific project objectives are to be achieved within the established guidelines of a contractual agreement. Project scope ranges from large projects (such as manufacturing operations) to small projects (such as exhibiting at conferences). Other examples include setting up new production sites, developing and testing new products and launching new products (marketing activities are also project-based activities). If a construction company wins a contract to build a new bridge, and construction requires specific materials and components to meet the project agreement within a specific time frame, there is a good chance that the project procurement team will be assigned to certain project activities.

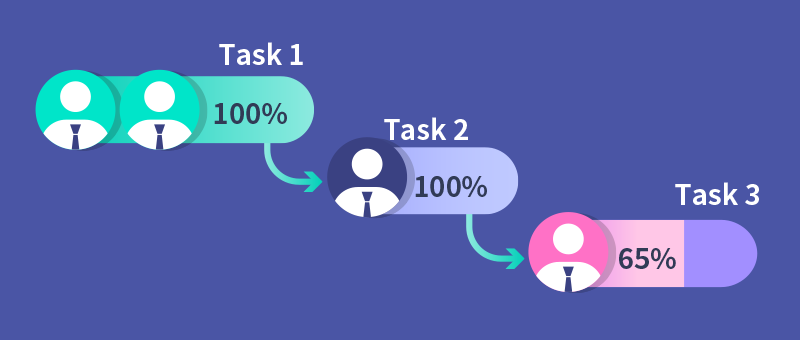

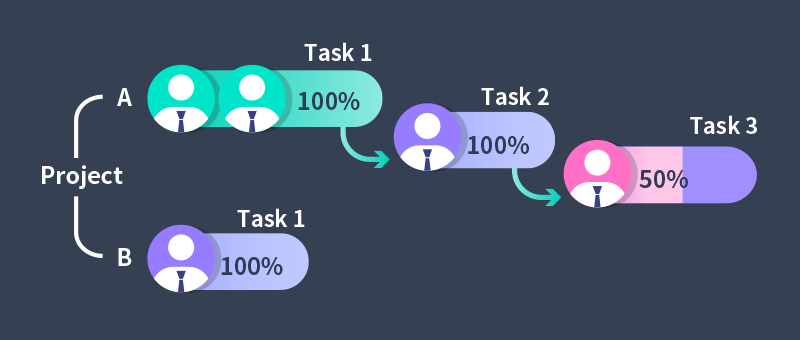

Project-based procurement groups procurement tasks within the framework of a project (such as planning procurement, creating bidding process, selecting shortlists, monitoring procurement, closing contracts and performance evaluation, etc.), or there are several similar groups placed in one or more project activities. It should be noted that the procurement tasks for each group in the project activities have a common theme and their goals and timelines/completion dates are very clear.

Another common procurement method is category-based procurement, where similar items are bundled into a category and managed as a single category. However, this would dilute or even erode the clarity of common goals and timelines. In the worst case, the project loses its connection with the project process, changes and costs completely due to the wrong way of bundling, and the procurement team of the project is forced into a passive state. Even if the project manager informs the procurement team promptly and clearly that the procurement needs or timing of the project has changed, the team cannot take appropriate action because they have placed all procurement tasks in the framework of category procurement. Because the architectures of the two frameworks are completely different, it is difficult for the procurement team to make effective adjustments across the frameworks.

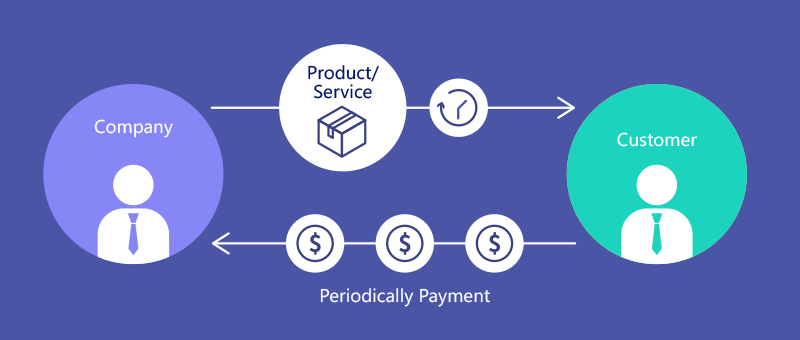

Overall, one of the biggest challenges in purchasing is the fragmentation of the supply chain, which creates a very diverse supply market: there are now a large number of suppliers around the world, and any company can do business with suppliers on demand during delivery (from small specialist companies to large multifunctional companies providing complete solutions). The challenge is to know who can provide an advantage in meeting a specific need.

This is a tough enough challenge at the category level. Doing this on a project-by-project basis adds difficulty if projects cannot be partially replicated: the inability to identify and sign up with suppliers within a specific projects timeline boosts pressure on the procurement process. Make sure that item procurement is captured in the automated process. Since suppliers of any project can be captured, you can ask them to bid on new project requirements.

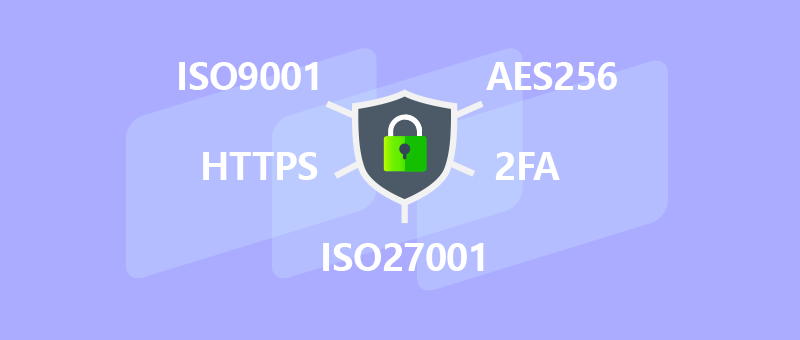

Project-based procurement is not conceptually complicated, but project procurement software is much more complex than category procurement software in design and creation, because project procurement software requires not only comprehensive procurement functions but comprehensive project management functions. It is not easy to associate the design between the two, so it is difficult for you to find the right project procurement software in the market.

Solution

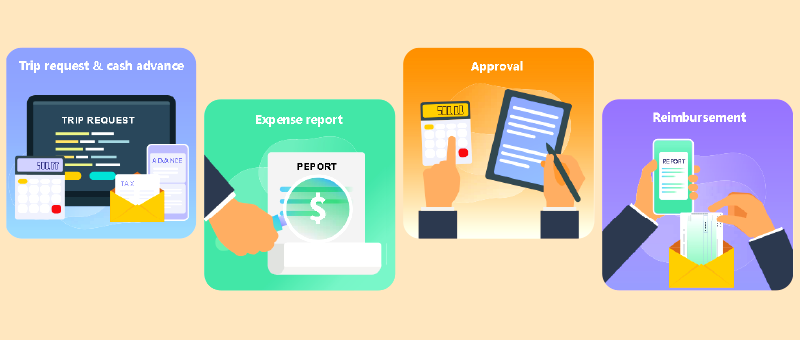

SRM combines its procurement and project management modules to support project-based procurement. The system allows you to plan and execute project activities, including the following procurement activities:

SRM combines its procurement and project management modules to support project-based procurement. The system allows you to plan and execute project activities, including the following procurement activities:

- Conduct supplier surveys and market research, including identifying potential suppliers and areas of concern at a business category or strategic level

- Start a quick quote, tendering (RFI, RFP, RFQ) or auction process

- Shortlist suppliers and evaluate existing opportunities to reduce costs, improve quality and increase revenue

- Negotiate the award of contracts and quality or service level agreements for new suppliers: agree on terms of supply, including the nature of the relationship and its subsequent management within the project framework

- Monitor procurement activities within the project: ensure obligation fulfillment and compliance

- Complete projects and related contracts and agreements

- Conduct supplier evaluations and performance feedback

SRM helps manage materials throughout the procurement project:

SRM helps manage materials throughout the procurement project:

- Material library (codes, specifications, inventory, workmanship, lead times...)

- Bill of Materials (BOM)

- Material distribution

- Inventory tracking

- Material release

- Material receipt

- Grouping

- Material distribution

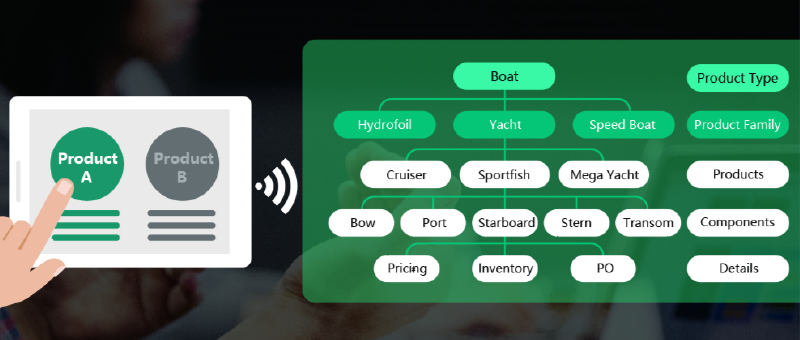

SRM is project-centric, with activities (such as supplier management, sourcing management, procurement management and material management) all embedded in the project, which is their external context.

SRM is project-centric, with activities (such as supplier management, sourcing management, procurement management and material management) all embedded in the project, which is their external context.