Beijing Consen Automation Technology Co., Ltd.

In recent years, with the support of a complete information management system, Consen has innovated its management model to enhance its competitiveness, seized opportunities and developed steadily to maintain its leading position in the industry. The ERP system implemented by Consen has brought a refined management model to the enterprise.

Relying on advanced technology and high-quality service, Beijing Consen Automation Technology Co., Ltd. (Consen) has made continuous leaps in the past 10 years, and successfully occupied the top spot in the field of industrial control. In recent years, with the support of a complete information management system, Consen has innovated its management model to enhance its competitiveness, seized opportunities and developed steadily to maintain its leading position in the industry. The  ERP system implemented by Consen has brought a refined management model to the enterprise and improved its competitiveness.

ERP system implemented by Consen has brought a refined management model to the enterprise and improved its competitiveness.

Background

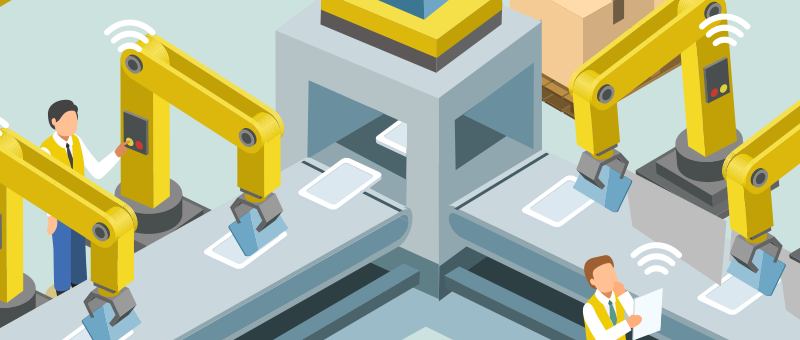

Established in 1999, Consen (belonging to China Automation Group Co., Ltd.) is a high-tech enterprise that combines research and development, production, sales, engineering services and after-sales service. It has been committed to providing users with an international advanced level of redundant fault-tolerant safety and critical control systems.

Through the unremitting efforts of all employees for more than 10 years, Consen has been developing steadily and become one of the preferred safety and key control system suppliers for users in petrochemical, coal chemical, natural gas pipeline, metallurgy, electric power, railway and other industries. In 2007, Consen was successfully listed in Hong Kong. At present, it has set up 27 offices to offer customers the high-quality localized services.

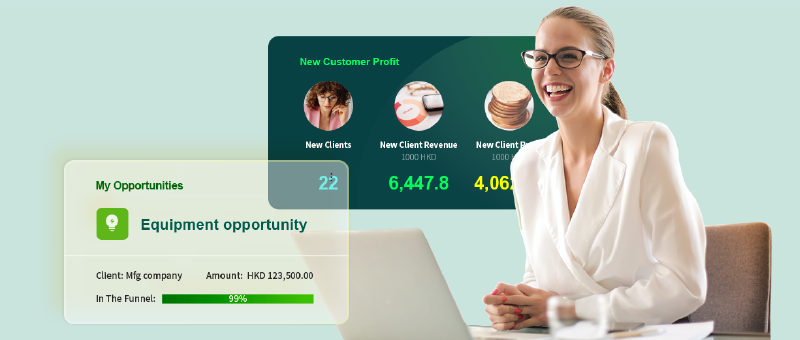

Entering the fast lane of development, Consen is facing new management challenges. In the past, Consen’s business opportunity follow-up and quotation were completed through Excel and reported regularly. However, Consen’s implementation involves a variety of materials and accessories, and requires the collaboration of multiple departments. Excel is just a management tool in the form of a spreadsheet, which does not allow the team to share information in real time and work collaboratively. As a result, it cannot effectively control contract costs, material costs and implementation costs, leading to project losses and manpower wastes for project settlement. This directly affects the profitability and development of the enterprise. Consen, who has always attached importance to enterprise management, responded quickly and decided to launch the ERP system, hoping to realize BOM standard management through ERP, improve work efficiency, and control project costs.

To choose the right ERP software, Consen did in-depth market research and product analysis, and finally chose ERP. Mr. Liu Tao, deputy general manager of Consen, said: “Before choosing

ERP. Mr. Liu Tao, deputy general manager of Consen, said: “Before choosing  , we saw that many ERP software could not meet the actual business needs of our company. After full understanding and evaluation, we finally chose

, we saw that many ERP software could not meet the actual business needs of our company. After full understanding and evaluation, we finally chose  given its complete product features and modern service technologies.”

given its complete product features and modern service technologies.”

Solution

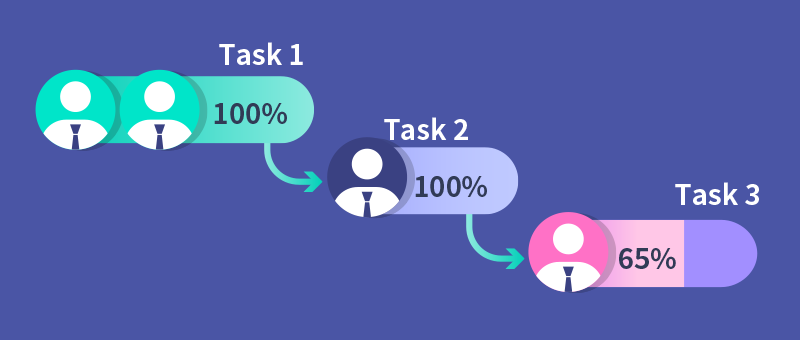

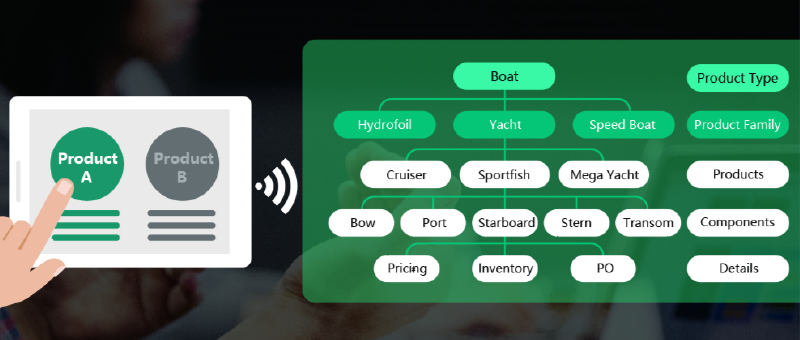

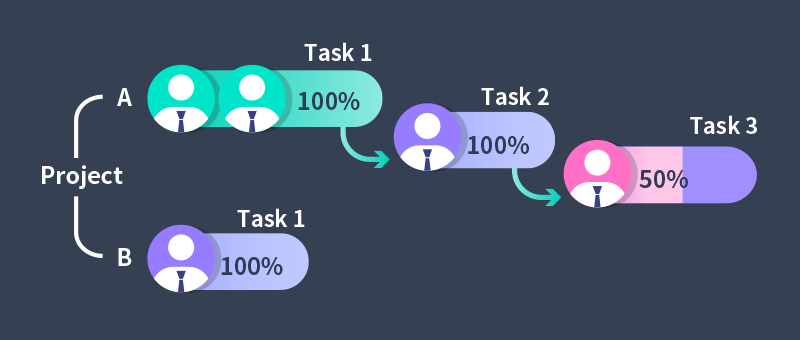

Through the in-depth analysis and sorting out of the implementation workflow of Consen’s project, the implementation team made a BOM-based solution for Consen’s sales and service teams. This solution integrated business opportunity, quotation, implementation and settlement and comprehensively solves the management difficulties through the following three methods.

implementation team made a BOM-based solution for Consen’s sales and service teams. This solution integrated business opportunity, quotation, implementation and settlement and comprehensively solves the management difficulties through the following three methods.

Open up the BOM circulation channel and standardize the management.

The launch of the ERP system has optimized the BOM circulation channel. Through the system, Consen has opened up the original multi-level and cross-departmental information flow channel, and integrated the personnel involved in system design, material quotation, manpower quotation, approval, procurement, execution and other departments to realize the seamless integration of BOM among different departments and process-style standardized management, ensuring the accuracy of BOM information and the timeliness of approval, and greatly improving work efficiency. Besides, the launch of

ERP system has optimized the BOM circulation channel. Through the system, Consen has opened up the original multi-level and cross-departmental information flow channel, and integrated the personnel involved in system design, material quotation, manpower quotation, approval, procurement, execution and other departments to realize the seamless integration of BOM among different departments and process-style standardized management, ensuring the accuracy of BOM information and the timeliness of approval, and greatly improving work efficiency. Besides, the launch of  ERP also seamlessly connects with Consen’s financial system to combine business and financial information and improve performance management.

ERP also seamlessly connects with Consen’s financial system to combine business and financial information and improve performance management.

Undertake variables to effectively track cost changes.

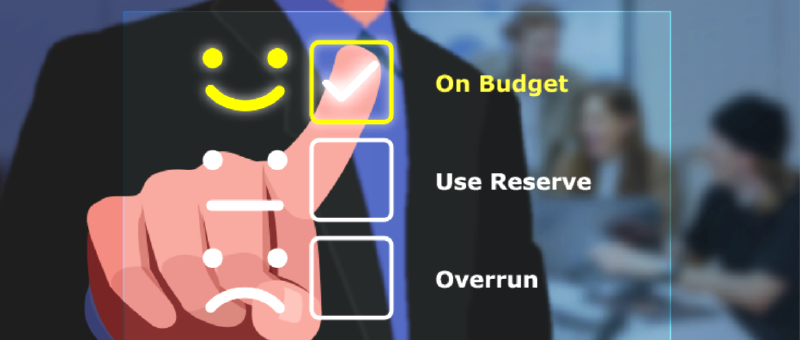

The BOM has undergone multiple approvals and refinements from business opportunity to settlement. From the first version of BOM to the finalized BOM, there are certain differences in data. The launch of ERP has solved the problem of variable tracking. Through the system, Consen has realized the real-time follow-up of BOM. For changes in BOM, the system summarizes, generates and saves different versions in real time, automatically compares components, remarks, demand and operating costs between different BOMs, and highlights the components with differences. Leaders only need to check the different versions of BOM to grasp the change in cost and realize cost monitoring easily.

ERP has solved the problem of variable tracking. Through the system, Consen has realized the real-time follow-up of BOM. For changes in BOM, the system summarizes, generates and saves different versions in real time, automatically compares components, remarks, demand and operating costs between different BOMs, and highlights the components with differences. Leaders only need to check the different versions of BOM to grasp the change in cost and realize cost monitoring easily.

Link data summary and convenient management

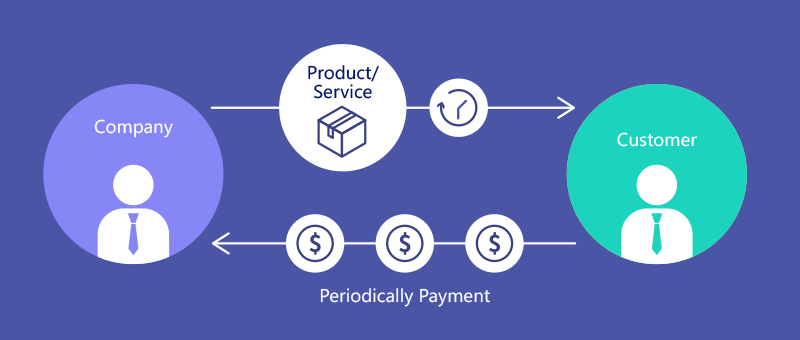

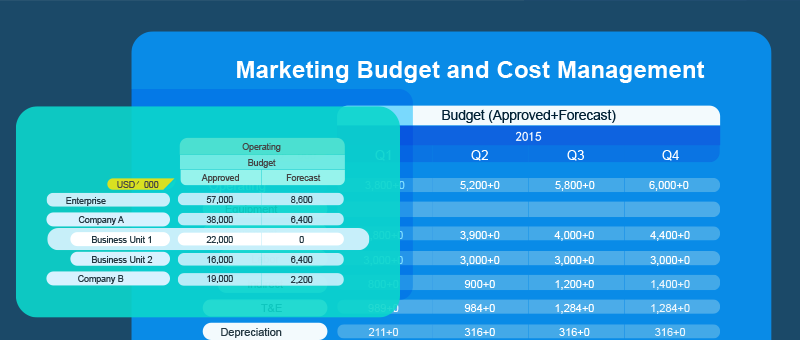

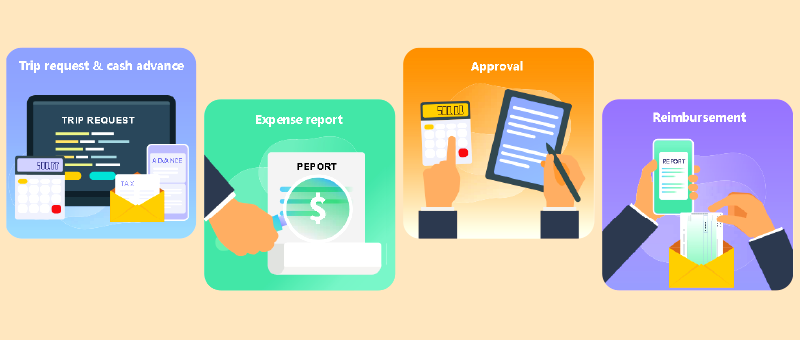

During the project implementation phase, Consen completes the phased delivery of the project through the delivery of system milestones. The system automatically generates invoices according to milestones in different stages, and then facilitates staged payment collection. Every time a collection is completed, the system summarizes and associates the latest data with relevant reports. Managers can check and track the payment status and profit rate of the contract through the report.

Based on the purchase and inventory changes generated by the BOM, Consen completes the purchase/in-out application and approval through the system. For the purchase and out-of-stock of the same project, the system provides purchase/inventory application/inventory delivery order merging processing, so that the order is directly associated with the project or contract, allowing Consen to easily track project costs.

During the project settlement stage, Consen’s project-related personnel create a packing list through the system, pack the BOM materials in the opportunity/strategy or contract and deliver them to the customer, and serve as a delivery record for easy enquiries.

As to the costs and incomes generated above, the system can automatically summarize them into related project reports. Consens management personnel can view the income and profit of the project through the report, and analyze and summarize them to provide a basis for decision-making.

ERP system has been in operation in Consen for nearly 3 years. Mr. Liu Tao, deputy general manager of Consen, concluded: “Through the system, the business information of each department can be fed back in time, which enhances the teamwork of each department and promotes the smooth development of work items. We are very satisfied with this choice. Information management is like a huge pusher, which promotes the steady development of the enterprise. With the support of

ERP system has been in operation in Consen for nearly 3 years. Mr. Liu Tao, deputy general manager of Consen, concluded: “Through the system, the business information of each department can be fed back in time, which enhances the teamwork of each department and promotes the smooth development of work items. We are very satisfied with this choice. Information management is like a huge pusher, which promotes the steady development of the enterprise. With the support of  ERP, I believe Consen will be able to climb the peak and create new glories again. ”

ERP, I believe Consen will be able to climb the peak and create new glories again. ”

ERP system implemented by Consen has brought a refined management model to the enterprise and improved its competitiveness.

ERP system implemented by Consen has brought a refined management model to the enterprise and improved its competitiveness. Background

Established in 1999, Consen (belonging to China Automation Group Co., Ltd.) is a high-tech enterprise that combines research and development, production, sales, engineering services and after-sales service. It has been committed to providing users with an international advanced level of redundant fault-tolerant safety and critical control systems.

Through the unremitting efforts of all employees for more than 10 years, Consen has been developing steadily and become one of the preferred safety and key control system suppliers for users in petrochemical, coal chemical, natural gas pipeline, metallurgy, electric power, railway and other industries. In 2007, Consen was successfully listed in Hong Kong. At present, it has set up 27 offices to offer customers the high-quality localized services.

Entering the fast lane of development, Consen is facing new management challenges. In the past, Consen’s business opportunity follow-up and quotation were completed through Excel and reported regularly. However, Consen’s implementation involves a variety of materials and accessories, and requires the collaboration of multiple departments. Excel is just a management tool in the form of a spreadsheet, which does not allow the team to share information in real time and work collaboratively. As a result, it cannot effectively control contract costs, material costs and implementation costs, leading to project losses and manpower wastes for project settlement. This directly affects the profitability and development of the enterprise. Consen, who has always attached importance to enterprise management, responded quickly and decided to launch the ERP system, hoping to realize BOM standard management through ERP, improve work efficiency, and control project costs.

To choose the right ERP software, Consen did in-depth market research and product analysis, and finally chose

ERP. Mr. Liu Tao, deputy general manager of Consen, said: “Before choosing

ERP. Mr. Liu Tao, deputy general manager of Consen, said: “Before choosing  , we saw that many ERP software could not meet the actual business needs of our company. After full understanding and evaluation, we finally chose

, we saw that many ERP software could not meet the actual business needs of our company. After full understanding and evaluation, we finally chose  given its complete product features and modern service technologies.”

given its complete product features and modern service technologies.” Solution

Through the in-depth analysis and sorting out of the implementation workflow of Consen’s project, the

implementation team made a BOM-based solution for Consen’s sales and service teams. This solution integrated business opportunity, quotation, implementation and settlement and comprehensively solves the management difficulties through the following three methods.

implementation team made a BOM-based solution for Consen’s sales and service teams. This solution integrated business opportunity, quotation, implementation and settlement and comprehensively solves the management difficulties through the following three methods.Open up the BOM circulation channel and standardize the management.

The launch of the

ERP system has optimized the BOM circulation channel. Through the system, Consen has opened up the original multi-level and cross-departmental information flow channel, and integrated the personnel involved in system design, material quotation, manpower quotation, approval, procurement, execution and other departments to realize the seamless integration of BOM among different departments and process-style standardized management, ensuring the accuracy of BOM information and the timeliness of approval, and greatly improving work efficiency. Besides, the launch of

ERP system has optimized the BOM circulation channel. Through the system, Consen has opened up the original multi-level and cross-departmental information flow channel, and integrated the personnel involved in system design, material quotation, manpower quotation, approval, procurement, execution and other departments to realize the seamless integration of BOM among different departments and process-style standardized management, ensuring the accuracy of BOM information and the timeliness of approval, and greatly improving work efficiency. Besides, the launch of  ERP also seamlessly connects with Consen’s financial system to combine business and financial information and improve performance management.

ERP also seamlessly connects with Consen’s financial system to combine business and financial information and improve performance management.Undertake variables to effectively track cost changes.

The BOM has undergone multiple approvals and refinements from business opportunity to settlement. From the first version of BOM to the finalized BOM, there are certain differences in data. The launch of

ERP has solved the problem of variable tracking. Through the system, Consen has realized the real-time follow-up of BOM. For changes in BOM, the system summarizes, generates and saves different versions in real time, automatically compares components, remarks, demand and operating costs between different BOMs, and highlights the components with differences. Leaders only need to check the different versions of BOM to grasp the change in cost and realize cost monitoring easily.

ERP has solved the problem of variable tracking. Through the system, Consen has realized the real-time follow-up of BOM. For changes in BOM, the system summarizes, generates and saves different versions in real time, automatically compares components, remarks, demand and operating costs between different BOMs, and highlights the components with differences. Leaders only need to check the different versions of BOM to grasp the change in cost and realize cost monitoring easily.Link data summary and convenient management

During the project implementation phase, Consen completes the phased delivery of the project through the delivery of system milestones. The system automatically generates invoices according to milestones in different stages, and then facilitates staged payment collection. Every time a collection is completed, the system summarizes and associates the latest data with relevant reports. Managers can check and track the payment status and profit rate of the contract through the report.

Based on the purchase and inventory changes generated by the BOM, Consen completes the purchase/in-out application and approval through the system. For the purchase and out-of-stock of the same project, the system provides purchase/inventory application/inventory delivery order merging processing, so that the order is directly associated with the project or contract, allowing Consen to easily track project costs.

During the project settlement stage, Consen’s project-related personnel create a packing list through the system, pack the BOM materials in the opportunity/strategy or contract and deliver them to the customer, and serve as a delivery record for easy enquiries.

As to the costs and incomes generated above, the system can automatically summarize them into related project reports. Consens management personnel can view the income and profit of the project through the report, and analyze and summarize them to provide a basis for decision-making.

ERP system has been in operation in Consen for nearly 3 years. Mr. Liu Tao, deputy general manager of Consen, concluded: “Through the system, the business information of each department can be fed back in time, which enhances the teamwork of each department and promotes the smooth development of work items. We are very satisfied with this choice. Information management is like a huge pusher, which promotes the steady development of the enterprise. With the support of

ERP system has been in operation in Consen for nearly 3 years. Mr. Liu Tao, deputy general manager of Consen, concluded: “Through the system, the business information of each department can be fed back in time, which enhances the teamwork of each department and promotes the smooth development of work items. We are very satisfied with this choice. Information management is like a huge pusher, which promotes the steady development of the enterprise. With the support of  ERP, I believe Consen will be able to climb the peak and create new glories again. ”

ERP, I believe Consen will be able to climb the peak and create new glories again. ”