is cool!

is cool! provides you a comprehensive

picture of recent, current, and likely future of your infrastructure and operations.

provides you a comprehensive

picture of recent, current, and likely future of your infrastructure and operations. is cool!

is cool! provides you a comprehensive

picture of recent, current, and likely future of your infrastructure and operations.

provides you a comprehensive

picture of recent, current, and likely future of your infrastructure and operations.

-

Quality Management

PPM Quality Management allows you to continue measuring the quality of all internal and external deliverables and taking corrective actions until the desired quality is achieved. Effective project quality management helps control project costs and lowers the risk of product failure or unsatisfied, unhappy clients.

PPM Quality Management allows you to continue measuring the quality of all internal and external deliverables and taking corrective actions until the desired quality is achieved. Effective project quality management helps control project costs and lowers the risk of product failure or unsatisfied, unhappy clients.

PPM provides you with quality planning, quality assurance and quality control workflows to conduct quality management of your projects.

PPM provides you with quality planning, quality assurance and quality control workflows to conduct quality management of your projects.

Quality Planning

PPM allows you to specify what each deliverable is supposed to do. What are its measurement matrices? Which experts are qualified to review it and determine whether it is passed or failed? If it fails, what needs to be done to rectify the problems? Answering these questions and others will help you to formulate the quality requirements of each of your deliverables.

PPM allows you to specify what each deliverable is supposed to do. What are its measurement matrices? Which experts are qualified to review it and determine whether it is passed or failed? If it fails, what needs to be done to rectify the problems? Answering these questions and others will help you to formulate the quality requirements of each of your deliverables.

PPM also allows you to set up quality review meetings and will automatically track them and their results.

PPM also allows you to set up quality review meetings and will automatically track them and their results.

Quality Assurance

PPM allows you to provide evidence to the stakeholders that all quality-related activities are being done as defined and promised. It ensures that safeguards are in place to guarantee that all expectations will be met with regard to quality outputs.

PPM allows you to provide evidence to the stakeholders that all quality-related activities are being done as defined and promised. It ensures that safeguards are in place to guarantee that all expectations will be met with regard to quality outputs.  PPM ensures that quality assurance is done to the products and services delivered by your project, as well as the processes and procedures used to manage the project.

PPM ensures that quality assurance is done to the products and services delivered by your project, as well as the processes and procedures used to manage the project.

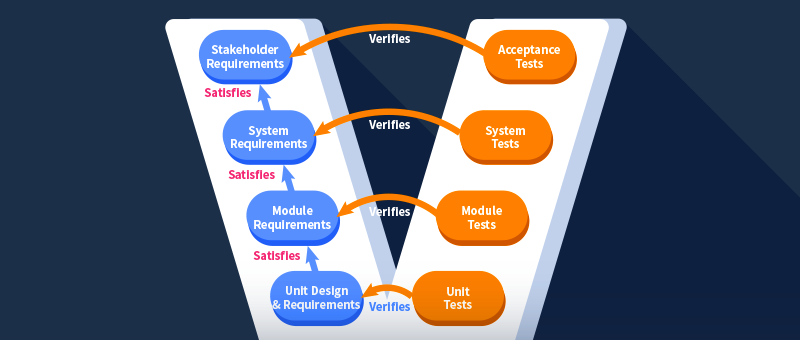

PPM allows you to specify and develop quality assurance tests and track the test results. You can also use matrices to determine whether or not the quality management plan is proceeding in an acceptable manner. By using both qualitative and quantitative metrics, you can effectively measure project quality with customer satisfaction. These tests or quality audits will help you predict and verify the achievement of goals and identify the need for corrective actions. Additionally, quality assurance tests will help you map quality metrics to quality goals, allowing you to report on the status of quality at periodic project review meetings.

PPM allows you to specify and develop quality assurance tests and track the test results. You can also use matrices to determine whether or not the quality management plan is proceeding in an acceptable manner. By using both qualitative and quantitative metrics, you can effectively measure project quality with customer satisfaction. These tests or quality audits will help you predict and verify the achievement of goals and identify the need for corrective actions. Additionally, quality assurance tests will help you map quality metrics to quality goals, allowing you to report on the status of quality at periodic project review meetings.

Quality Control

PPM provides you with workflows to ensure quality standards. These include identifying, analyzing, and correcting problems. While quality assurance occurs before a problem is identified, quality control is reactionary and occurs after a problem has been identified, and suggests methods of improvement.

PPM provides you with workflows to ensure quality standards. These include identifying, analyzing, and correcting problems. While quality assurance occurs before a problem is identified, quality control is reactionary and occurs after a problem has been identified, and suggests methods of improvement.

PPM helps you to monitor your project outputs and determines compliance with applicable standards. It also helps you to identify project risk factors, their mitigation and looks for ways to prevent and eliminate unsatisfactory performance.

PPM helps you to monitor your project outputs and determines compliance with applicable standards. It also helps you to identify project risk factors, their mitigation and looks for ways to prevent and eliminate unsatisfactory performance.

Quality control can also ensure that the project is on budget and schedule. Monitoring the project outputs can be done through deliverable review and acceptance testing in

PPM. By catching deliverables that aren't meeting the agreed-upon standards throughout, you will be able to simply adjust your direction rather than having to entirely redo certain aspects.

PPM. By catching deliverables that aren't meeting the agreed-upon standards throughout, you will be able to simply adjust your direction rather than having to entirely redo certain aspects.