Special News

What is sourcing in procurement?

2024-10-29

Sourcing (Strategic Sourcing) is a crucial part in modern enterprise procurement management. It refers to the process of selecting the best suppliers through market research, supplier evaluation, negotiation, etc., to ensure the stable supply of materials required by the enterprise. It is not only a process of finding and evaluating potential suppliers, but also includes optimizing the supply chain, reducing procurement costs, and enhancing supply chain efficiency. In the context of a globalized economy, sourcing has become an important means for enterprises to enhance their competitiveness.

1.The Importance of sourcing in procurement

(1)Improve the Cost-Effectiveness of Enterprises

Sourcing helps enterprises find the most cost-effective partners among different suppliers through detailed market analysis and supplier evaluation. By negotiating with suppliers, signing long-term contracts, and choosing competitive quotes, enterprises can effectively reduce procurement costs. In addition, by optimizing supplier relationships and negotiating contract terms, enterprises can further reduce costs while maintaining quality and achieve efficient use of funds.

(2)Optimize Supply Chain Management

A successful sourcing can improve the stability and flexibility of the supply chain. By finding reliable suppliers, enterprises can ensure the continuity of material supply, thereby reducing inventory pressure and the risk of stockouts. At the same as, supplier cooperation in the sourcing process can also bring new technologies or services to enterprises, helping them optimize their production processes and improve the overall supply chain efficiency.

(3)Reduce Supply Chain Risks

Sourcing focuses not only on price, but also on the stability and long-term cooperation potential of suppliers. Through in-depth background investigations, financial analyses, and reputation evaluations, enterprises can detect potential risks as early as possible, such as supplier bankruptcy, insufficient production capacity, or quality problems. Selecting suppliers with long-term cooperation capabilities can reduce the risk of supply chain disruption caused by supplier changes and ensure the operational stability of the enterprise.

(4)Promote Sustainable Development

As sustainable development has gradually become an important goal of enterprise operations, sourcing also plays a role in promoting a green supply chain. In the sourcing process, enterprises can consider choosing suppliers with environmental awareness and social responsibility to ensure that their supply chains not only meet quality requirements, but also comply with environmental standards and social moral norms. This strategy not only helps improve the social image of the enterprise, but also avoids legal and reputational risks caused by non-compliant supplier behavior.

(5)Strengthen Supplier Cooperative Relationships

Sourcing is not just about finding the cheapest suppliers, but more about establishing long-term, mutually beneficial cooperation relationships. Through negotiation and cooperation in the sourcing process, enterprises and suppliers can achieve a win-win situation. In long-term cooperation, suppliers can provide customized products and services for enterprises, improving supply chain efficiency. And enterprises can also help suppliers plan production through stable procurement requirements, improving their efficiency and achieving sustainable development for both parties.

2.The Process of sourcing in procurement

(1)Demand Analysis

The first step of sourcing is to accurately understand the enterprises procurement needs. The enterprise needs to clarify the specific information such as the type, quantity, quality requirements, and delivery cycle of the materials to be purchased. Through detailed demand analysis, the procurement department can clearly define the sourcing goals and provide a basis for the next step of supplier screening.

(2)Market Research

After determining the procurement needs, the enterprise needs to conduct extensive market research. The purpose of market research is to understand which potential suppliers are in the current market, their market share, reputation, technical ability, and price level, etc. Through market research, the enterprise can have a comprehensive understanding of the overall situation of suppliers and preliminarily determine a suitable list of suppliers.

(3)Supplier Screening

On the basis of market research, the enterprise will further screen potential suppliers. This stage usually includes multiple aspects of evaluation, such as the financial situation, production capacity, technical level, quality control system, and past cooperation records of suppliers. The enterprise can also evaluate the actual ability of suppliers through on-site inspections or third-party audits to ensure that they meet the enterprises long-term cooperation standards.

(4)Inquiry and Negotiation

After determining the suppliers, the enterprise will send inquiry sheets to these potential suppliers and ask them to provide quotes. After receiving the quotes, the enterprise will compare the prices, services, delivery periods, etc. of various suppliers and begin price negotiations. The focus of the negotiation is not only on price, but also on payment conditions, breach of contract terms, quality assurance, etc. Through negotiation, the enterprise and suppliers can reach an agreement and sign a contract that conforms to the interests of both parties.

(5)Signing the Contract

After the negotiation is completed, the enterprise and suppliers will sign a formal procurement contract. The contract will clearly define the rights and duties of both parties, including price, delivery period, quality standard, payment method, and breach of contract treatment, etc. Signing the contract marks the end of the sourcing process, and the suppliers will begin to supply according to the conditions agreed in the contract.

(6)Supplier Management

The work of sourcing does not end with the signing of the contract. The enterprise needs to continuously manage and evaluate suppliers to ensure that they deliver on time, the quality is qualified, and they can respond to market changes and adjustments in enterprise needs. By establishing a good supplier management mechanism, the enterprise can gain more advantages in future cooperation and improve the overall efficiency of the supply chain.

3.The Best Practices of sourcing in procurement

(1)Use Digital Tools

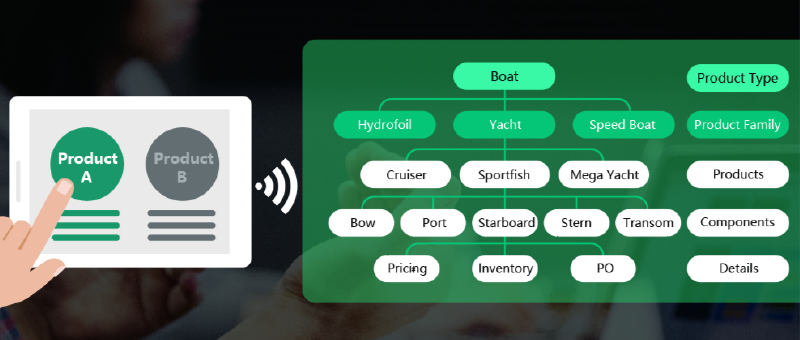

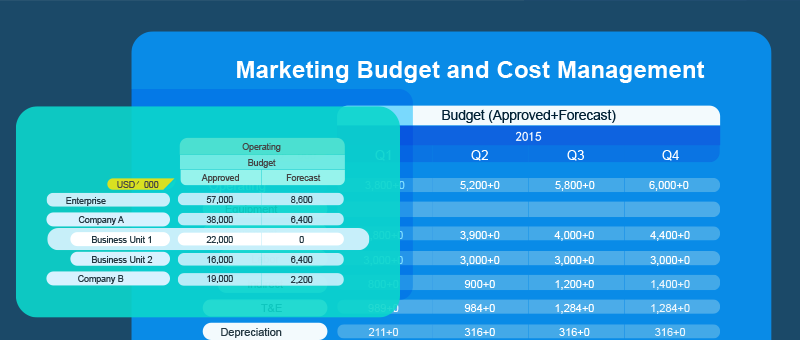

In modern sourcing in procurement, using digital tools such as e-tendering platforms, supplier management systems, and big data analysis tools can greatly improve efficiency. Through these tools, the enterprise can more easily conduct market analysis, supplier screening, and contract management, reduce human errors and time wastage, and improve the accuracy of sourcing decisions.

(2)Establish Strategic Partnerships

Sourcing is not just a one-time procurement activity, but a long-term strategic process. By establishing strategic partnerships with key suppliers, the enterprise can obtain more competitive prices and better services. Strategic partnerships can also help the enterprise maintain the flexibility and stability of the supply chain when the market changes, thereby improving the enterprises market competitiveness.

(3)Regularly Evaluate Supplier Performance

To ensure the continued qualification of suppliers, the enterprise should regularly evaluate the performance of suppliers. The evaluation content can include the timeliness of supplier delivery, product quality, price stability, after-sales service, etc. Through regular evaluation, the enterprise can detect potential problems of suppliers in time and make corresponding adjustments according to the evaluation results, such as optimizing the list of suppliers or re-negotiating contract terms.

(4)Balance Cost and Quality

In the sourcing process, although cost is an important consideration factor, it should not be at the expense of quality. The enterprise needs to find a balance between cost and quality to ensure that the selected suppliers can not only provide competitive prices, but also guarantee high-quality products or service. In this way, the enterprise can maintain a stable supply chain and market competitiveness in the long term.

Through the above content, we hope you can have a more in-depth understanding of sourcing. In the modern business environment, sourcing has become an important tool for enterprises to optimize the supply chain, reduce costs, and enhance competitiveness. For teams that want to further improve their procurement management level, they can use professional tools such as 8Manage SRM for assistance. 8Manage SRM website: https://www.8manage.cn/srm_index.html

Related Questions FAQs

1.What is the difference between sourcing and procurement?

Sourcing is a strategic procurement method that focuses on reducing costs and enhancing supply chain efficiency through long-term cooperation. Compared with ordinary procurement, sourcing pays more attention to the long-term cooperation potential, quality assurance, and supply chain optimization of suppliers. Procurement is usually a transaction for short-term needs, while sourcing is achieved through detailed market analysis and negotiation to form a long-term cooperation relationship.

2.How does an enterprise reduce risks in sourcing in procurement?

An enterprise can reduce risks in sourcing in many ways, including: conducting a comprehensive background investigation and credit evaluation of suppliers, formulating detailed contract terms and a breach of contract treatment mechanism, and regularly evaluating the performance of suppliers. Using a multi-supplier strategy is also an effective way to reduce risks, so that even if one supplier has a problem, it will not affect the stability of the entire supply chain.

3.What kind of enterprises are suitable for sourcing in procurement?

Sourcing is suitable for medium and large enterprises, especially those with high requirements for supply chain stability, cost control, and long-term cooperation. For enterprises that need to frequently purchase and have a complex supply chain, sourcing can help them optimize the procurement process, reduce long-term costs and enhance the flexibility and anti-risk ability of the supply chain. For small enterprises, ordinary procurement may be more flexible.

Most popular

How IPD drives product R&D toward commercial success

Top procurement management systems to elevate your business in 2025

Are your project managers ready for AI?

Related articles

Real estate procurement management system selection guide

2025-02-13

2025 Guide to supplier management systems for manufacturers

2025-01-24

Hotel procurement and cost control: Your key to higher revenue

2025-01-16

Top procurement management systems to elevate your business in 2025

2025-01-10

Key nodes in automotive supply chain: Logistics, procurement, cost

2025-01-08

Previous Article >

What is Business Project Management?

What is Business Project Management?