Special News

Key Stages in the Procurement Process

2024-09-02

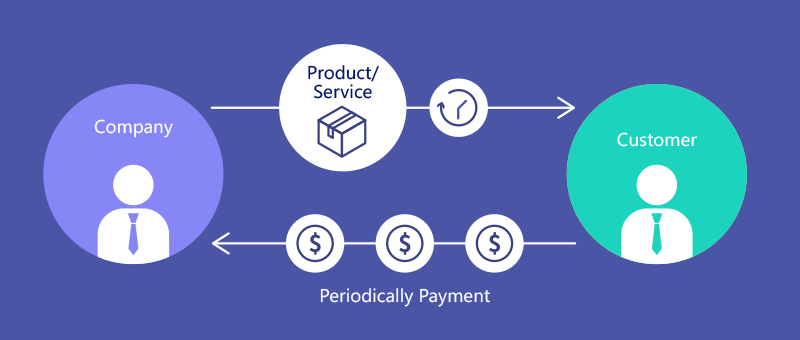

Procurement refers to the process by which a company acquires products or services from the market under specific conditions to ensure its production activities. It is a strategic process that involves identifying, selecting, negotiating, and finalizing contracts with suppliers. Typically, procurement teams strive to secure competitively priced supplies that offer maximum value, aiming to design a procurement process that ensures high-quality outputs.

However, the procurement process in many companies often experiences delays, typically due to inadequate procedures or a lack of clarity on how the process should be carried out. Simplifying the process can accelerate procurement, so establishing effective methods to handle changes is crucial, as it eliminates uncertainties about how tasks should be performed.

Key Stages in the Procurement Process

1. Identifying Procurement Needs

The first step for a company is to determine its need for a particular product or service. This requires a deep understanding of the businesss specific requirements. Product details might include technical specifications, materials, service characteristics, or part numbers. At this stage, its best to consult all business departments affected by the procurement decision to ensure that the purchased items accurately reflect each departments needs.

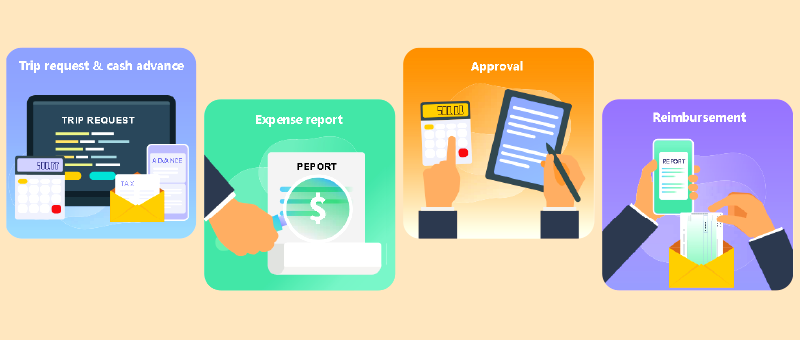

2. Developing a Procurement Plan

When employees or business units need to purchase a significant amount of new supplies or services, they submit a formal procurement request. Upon receiving the procurement task, procurement staff must develop a detailed work plan. Specifically, they need to conduct market research on the materials to be purchased, including an analysis of product prices, specifications, and suppliers, to determine the procurement method, timing, transportation methods, and payment methods.

3. Screening Suppliers

With a clear list of requirements and approved procurement requests, procurement staff can directly send the procurement information to suppliers within the companys supply chain. For suppliers outside the supply chain, procurement staff can select those with high quality, low prices, timely delivery, and excellent service through information gathering.

4. Negotiating Prices and Terms

A good way to negotiate prices is by obtaining and comparing quotes from suppliers. Each quote must be thoroughly reviewed and compared with others. Once the final quote is received, the terms should be immediately documented. The negotiation step is considered a crucial foundation for ensuring a quality procurement process.

5. Signing the Contract

After selecting a preferred supplier, the procurement staff must also communicate with the supplier regarding quality, delivery times, and after-sales service, ultimately formalizing these conditions in a procurement contract. The signing of the procurement contract signifies the official commencement of the procurement collaboration between the two parties.

Tools for Simplifying the Procurement Process

Procurement has become an indispensable long-term strategy for businesses, compared to past processes. As procurement processes become increasingly complex, companies are adopting modern procurement software to simplify these convoluted procedures. By choosing professional software tools, companies can effectively compete in todays challenging environment. The following technologies in the new-generation 8Manage SRM procurement management system are worth considering:

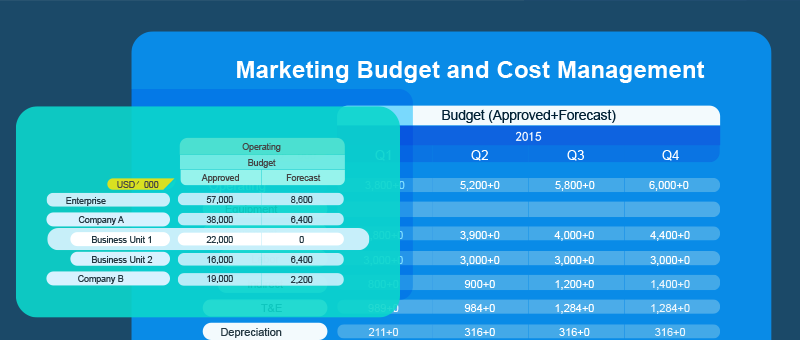

1. Real-time Spend Analysis

The 8Manage SRM system optimizes procurement through advanced data analysis. It aggregates, cleans, and categorizes data, increasing visibility into expenditures and allowing for improved spend analysis. You can gain real-time insights into your cost-saving plans and their impact, eliminating redundancy and errors in data capture and tracking.

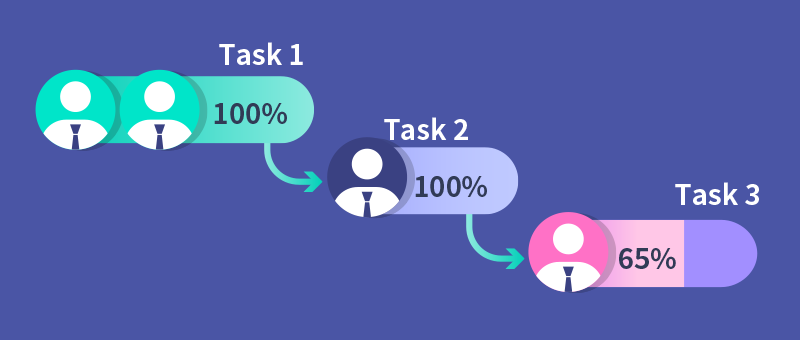

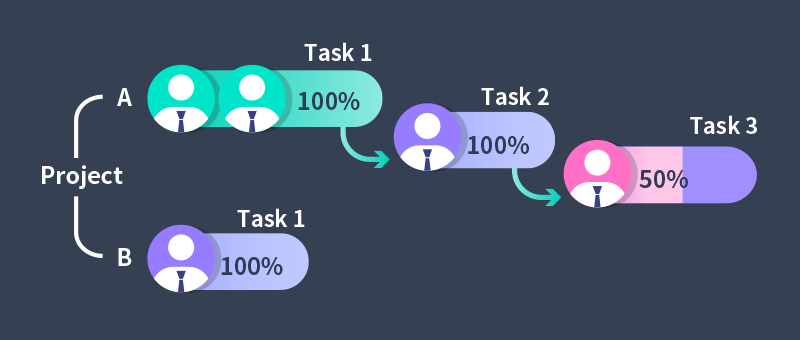

2. Automated E-Procurement

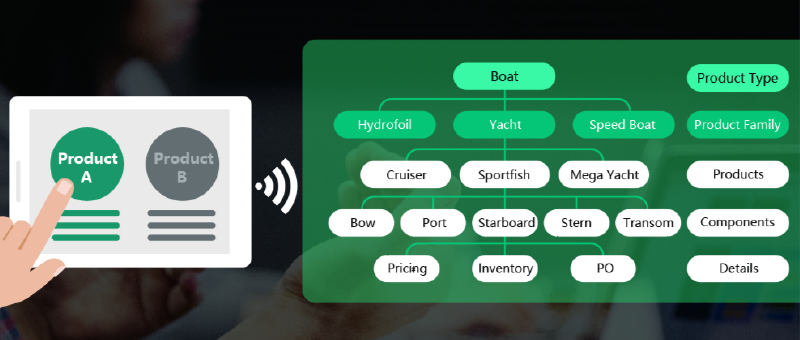

The system supports end-to-end procurement processes, covering everything from procurement budgeting, supplier management, item management, procurement requirements, planning, inquiries, bidding, tenders, procurement contracts, purchase orders, delivery, payment settlement, to supplier performance evaluation. The system provides real-time procurement progress updates and decision-making support, allowing you to monitor the procurement process through the approval workflow.

3. Supplier Relationship Management

8Manage SRMs analytics and business intelligence tools help identify potential suppliers. The information gathered through these methods can also assist stakeholders in making informed decisions about future actions. With every transaction, the 8Manage SRM procurement management system automatically collects and updates supplier performance information, making it easier to optimize suppliers effectively.

4. Contract Management

The system provides a renewal overview, allowing procurement staff to easily view all contracts nearing renewal. Additionally, 8Manage supports automatic generation of new procurement contracts based on renewal settings, saving time and effort while ensuring more accurate information.

Conclusion

Although companies have different procurement needs and processes, choosing a modern, automated procurement management system can significantly accelerate procurement processes, saving both time and resources. Procurement is not just about acquiring goods and services externally; it relies on strategic planning and careful observation to meet cost, timeline, and quality goals. For any company looking to grow rapidly and withstand the test of time, procurement is a critical component of business operations.

Most popular

How IPD drives product R&D toward commercial success

Top procurement management systems to elevate your business in 2025

Are your project managers ready for AI?

Related articles

How to choose the best procurement management software for your business?

2025-03-07

Top 5 procurement and tender management systems in 2025: Rankings and reviews

2025-03-05

Top 6 procurement management software for businesses in Hong Kong

2025-02-26

Real estate procurement management system selection guide

2025-02-13

2025 Guide to supplier management systems for manufacturers

2025-01-24

Previous Article >

The Importance of Project Milestones

The Importance of Project Milestones

Next Article >

Why you need project cost management software

Why you need project cost management software