Inventory Management

Challenge

The lifeblood of a business is delivering products to customers on time, but managing inventory is a daunting task whose processes and outcomes affect every aspect of the business. Mastering your inventory and managing it effectively can help you meet demand and generate sales. Here are our most common purchase-sell-stock challenges:

Inconsistent tracking

Using manual inventory trackers in disparate software and spreadsheets is time-consuming, redundant, and error-prone. Even small businesses can benefit from a centralized inventory tracking system that includes accounting functions.

Warehouse efficiency

Warehouse purchase-sell-stock management control is labor-intensive and involves multiple steps, including receiving and shelving, picking, packing, and shipping. The challenge is to perform all these tasks in the most efficient way.

Inaccurate inventory data

You need to know exactly what inventory you have at any given moment. Gone are the days when inventory was calculated annually through an all-hands approach.

Changing needs

Customer needs are constantly changing. Holding too much might keep you from selling outdated inventory, while holding too little might prevent you from fulfilling customer orders. Ordering strategies for core items and techniques to create and execute inventory plans help compensate for changing demand.

Limited visibility

When your inventory is difficult to identify or locate in the warehouse, this results in incomplete, inaccurate or delayed shipments. Receiving and finding the right inventory is critical to efficient warehouse operations and a positive customer experience.

Problem inventory

Perishable and fragile inventory requires a dedicated care and storage plan. High-value inventory needs specific loss prevention strategies and inventory controls.

Supply chain complexity

A global supply chain that changes every day puts a burden on your inventory planning and management operations. Manufacturers and wholesale distributors who decide when, where and how your inventory is shipped require flexibility and offer unpredictable lead times.

Manage warehouse space

Managing space effectively can be a daunting task. Using  SRM to plan and design warehouse space can help you better control the timing of new inventory deliveries and take into account important factors such as available space.

SRM to plan and design warehouse space can help you better control the timing of new inventory deliveries and take into account important factors such as available space.

Insufficient order management

One of the most common challenges of sound purchase-sell-stock management is preventing oversold products and inventory depletion. Using  SRM’s historical data trends will assist you in accurately forecasting customer orders.

SRM’s historical data trends will assist you in accurately forecasting customer orders.

Expand product portfolio

Many online retail strategies eliminate the need for large warehouse distribution centers. These strategies make it easier to expand inventory and diversify product portfolios, but require technology and resources for ordering, shipping and tracking.

Backlog

Too much inventory on hand can be just as problematic as too little. Overstock can impact business cash flow and cause inventory-related issues such as storage and losses.

Stock loss

Loss of inventory due to spoilage, damage or theft can be a supply chain issue. It requires identifying, tracking and measuring problem areas.

Bad production plan

Production planning is critical to avoid delayed manufacturing and cost overruns. If done poorly, it can affect sales forecasts and project schedules.

Lack of expertise

It is difficult to find skilled inventory managers who are versed in the latest technology and can improve inventory strategies. It is not enough to simply upgrade your purchase-sell-stock platform with tons of features. You need effective management.

Poor communication

Communication and collaboration are key. Identifying inventory trends and finding ways to improve is more difficult when departments are indifferent to sharing information.

Inefficient processes

When inventory is small and there is only one warehouse location to manage, a low-tech manual purchase-sell-stock program may not seem like a daunting challenge. But inefficient, labor-intensive, and low-tech standard operating procedures are hard to scale as sales increase and inventories expand.

Solution

The right purchase-sell-stock platform can automate processes, and improve inventory practices and customer experience.  SRM provides a range of local purchase-sell-stock management and control functions to help overcome some of its biggest challenges. Using it, you can track inventory across multiple locations, automatically manage reorder points as well as forecast demand and plan production and distribution.

SRM provides a range of local purchase-sell-stock management and control functions to help overcome some of its biggest challenges. Using it, you can track inventory across multiple locations, automatically manage reorder points as well as forecast demand and plan production and distribution.

Centralized tracking

Consider upgrading to tracking software with automation for reordering and purchasing.  SRM contains a cloud-based centralized database for accurate, automatic inventory updates and real-time data backup

SRM contains a cloud-based centralized database for accurate, automatic inventory updates and real-time data backup

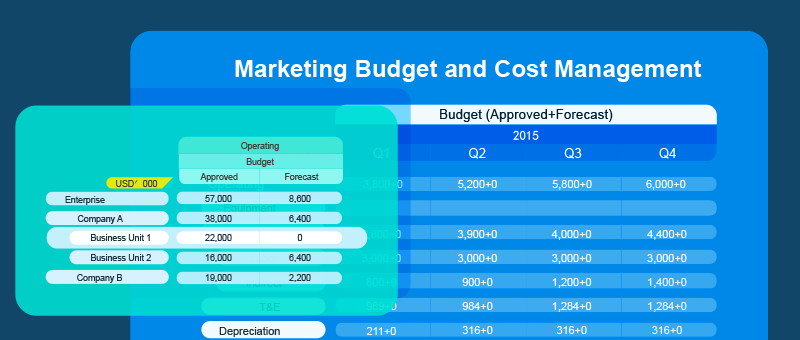

Transparent performance

>Measure and report warehouse performance metrics such as inventory turns, customer satisfaction, and order processing speed to address warehouse inefficiencies. Share this data with employees and suppliers at  SRM.

SRM.

Inventory audit

Frequent inventory audit processes, such as weekly counts, reduce human error and provide more accurate, up-to-date inventory data to manage cash flow. Organize audits by category and cycle count a smaller inventory sample on a predictable schedule for more accurate financial data.

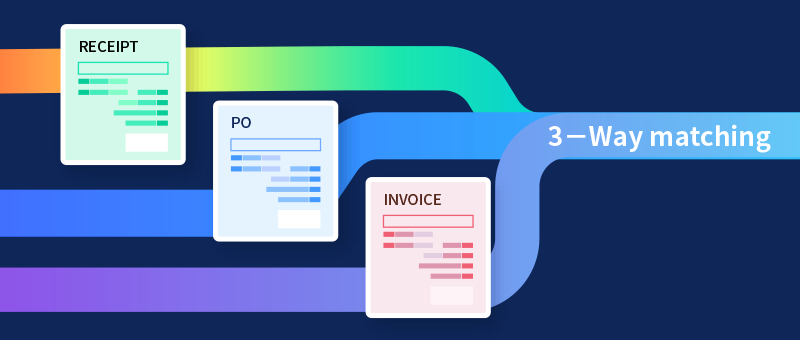

Paperless

SRM offers job-appropriate inventory tools to employees. They need software to replace manual inventory documentation as well as paperless transactions for invoices and purchase orders.

SRM offers job-appropriate inventory tools to employees. They need software to replace manual inventory documentation as well as paperless transactions for invoices and purchase orders.

Problem control

Use  SRM to manage problematic inventory such as perishable inventory, fragile equipment or obsolete materials. Perform regular preventive maintenance on stored machinery and equipment inventory, if required by the manufacturer. Regularly review catalog data on problem inventory location, cost and quantity to monitor shelf life and prevent waste.

SRM to manage problematic inventory such as perishable inventory, fragile equipment or obsolete materials. Perform regular preventive maintenance on stored machinery and equipment inventory, if required by the manufacturer. Regularly review catalog data on problem inventory location, cost and quantity to monitor shelf life and prevent waste.

Measure service levels

Monitor and track supplier data such as shipping errors, damaged or defective products, and missed delivery appointments with  SRM. Measure supplier performance to identify and fix supply chain disruptions, reduce complexity and simplify logistics.

SRM. Measure supplier performance to identify and fix supply chain disruptions, reduce complexity and simplify logistics.

Safety stock and reorder alerts

Maintain safety stock through  SRM to offset supply chain disruptions and help manage increased lead times due to changing international competition for raw materials. Proper inventory planning is helpful for operations to adapt to dynamic global supply chains.

SRM to offset supply chain disruptions and help manage increased lead times due to changing international competition for raw materials. Proper inventory planning is helpful for operations to adapt to dynamic global supply chains.

Create inventory classifications in  SRM to manage changing trends, such as packaging initiatives to reduce plastic waste. Sort inventory by package type, size, and product. Use this information to better control shipping costs and storage locations.

SRM to manage changing trends, such as packaging initiatives to reduce plastic waste. Sort inventory by package type, size, and product. Use this information to better control shipping costs and storage locations.

Multi-location warehousing

Use  SRMs multi-location warehouse management features to track and control expanding inventory. Keep an eye on warehouse locations and in-transit inventory with automatic inventory tracking alerts and scheduling, and take advantage of receiving and inbound planning.

SRMs multi-location warehouse management features to track and control expanding inventory. Keep an eye on warehouse locations and in-transit inventory with automatic inventory tracking alerts and scheduling, and take advantage of receiving and inbound planning.

Reduce human error

With SRMs inventory control processes, such as blind collection using barcodes and mobile scanners, you can prevent human error, inventory manipulation and shrinkage due to theft or negligence.

SRMs inventory control processes, such as blind collection using barcodes and mobile scanners, you can prevent human error, inventory manipulation and shrinkage due to theft or negligence.

Plan for future inventory

SRM provides planning purchasing demand tools to help you determine your next inventory needs like considering the availability of the top 20% of inventory that generates 80% of customer demand.

SRM provides planning purchasing demand tools to help you determine your next inventory needs like considering the availability of the top 20% of inventory that generates 80% of customer demand.