-

Cost benefits

helps your teams to maximize their abilities to save cost by allowing them to focus on the total cost of ownership (TCO) of each purchase and control each procurement step .

helps your teams to maximize their abilities to save cost by allowing them to focus on the total cost of ownership (TCO) of each purchase and control each procurement step .

Total cost of ownership (TCO)

The total cost of ownership (TCO) is the cost to buy something plus the cost to operate it over its useful life. The idea is to take into consideration the total cost that a business will incur to operate an asset, not just the upfront acquisition cost. The operating cost includes maintenance, installation, implementation, downtime during installation/implementation, training required to use the asset, disposal, licensing and upgrades.

When calculating the operating cost, it’s important to adjust future costs to today’s value, taking into account the value of the money and the timing of the costs. As well, you should subtract the salvage value at the end of the asset’s life.

Why calculating TCO is important

Calculating the TCO is important when comparing capital investment options to gauge the best value. Businesses often make the mistake of ignoring TCO and focusing only on upfront costs when evaluating capital investments. For example, printer A may cost less to buy than printer B, but a lower cost of ink cartridge replacements may make printer B a much better value.

Also, be sure to account for differences in the length of the asset’s lifespan. If printer A has a useful life of five years while printer B’s lifespan is 10 years, printer B will likely offer better value.

Calculating TCO can unravel hidden costs

Complex spend management can’t be done well by only looking at the price quoted. Hidden factors such as inventory, logistics, switching costs and embedded services must all be rolled in to understand the TCO for any decision.

Control cost in each of your steps

SRM can help you control all procurement steps and streamline your purchases to avoid over and under buying, automate your process, and efficiently oversee your suppliers’ performance.

SRM can help you control all procurement steps and streamline your purchases to avoid over and under buying, automate your process, and efficiently oversee your suppliers’ performance.  SRM can also centralize all your data and provide you with real-time visibility for purchase requirements, suppliers and products. You will also know your stock flow and when to replenish inventory, as well as opportunities to increase profit, while monitoring and building a long-term relationship with suppliers.

SRM can also centralize all your data and provide you with real-time visibility for purchase requirements, suppliers and products. You will also know your stock flow and when to replenish inventory, as well as opportunities to increase profit, while monitoring and building a long-term relationship with suppliers.

Procurement costs are one of the main factors that can affect a company’s profitability.

SRM can offer you valuable data to decrease costs, improve supplier management, and add up to your bottom line. The following is the list of common procurement cost reduction strategies that many organizations have implemented using

SRM can offer you valuable data to decrease costs, improve supplier management, and add up to your bottom line. The following is the list of common procurement cost reduction strategies that many organizations have implemented using  SRM:

SRM:

Ensure supplier discounts

Seeking discounts from suppliers is one of the best ways to reduce procurement costs.

SRM provides you with current and historical pricing information in real-time to allow you to see the room for discounts.

SRM provides you with current and historical pricing information in real-time to allow you to see the room for discounts.

SRM allows you to use different purchasing mechanisms such as blanket contract and standing offer to obtain goods and services from a supplier at a fixed price frequently for a particular duration.

SRM allows you to use different purchasing mechanisms such as blanket contract and standing offer to obtain goods and services from a supplier at a fixed price frequently for a particular duration.

SRM also manages your long-term relationship with your suppliers which would also give you more bargaining power to reach successful negotiations.

SRM also manages your long-term relationship with your suppliers which would also give you more bargaining power to reach successful negotiations.

Review contracts to avoid spending leakage

Spending leakage can happen outside the contract terms.

SRM helps you monitor all purchases to ensure they comply with contract terms, including payment terms. Non-compliant purchases can cause spending leakage. However,

SRM helps you monitor all purchases to ensure they comply with contract terms, including payment terms. Non-compliant purchases can cause spending leakage. However,  SRM can help you identify and find remedies to prevent them.

SRM can help you identify and find remedies to prevent them.

If the leakage goes unnoticed, it will keep happening and gradually build up a big cost. Therefore, leveraging

SRM to avoid leakage is very important.

SRM to avoid leakage is very important.

Consolidate spending

Consolidating spending on a few suppliers can bring more benefits than spreading your purchasing across many suppliers. Sourcing more products from the same supplier enables economies of scale: The more you spend with one vendor, the better chances you can negotiate a discount.

SRM allows you to combine tens or even hundreds of purchase requests into one so that you can better control the number of suppliers that you want to order from based on your preset supplier quotas.

SRM allows you to combine tens or even hundreds of purchase requests into one so that you can better control the number of suppliers that you want to order from based on your preset supplier quotas.

Review purchasing needs

Before deciding to purchase anything, evaluate what’s in your warehouse. If there are unused products, think about how to deal with them. Overstocked inventory is “dead money”, which costs you resources to store and is at risk of being damaged or becoming obsolete.

SRM provides you with inventory information along with the list of goods in the purchase request so that you can decide whether fulfilling the purchase request with a request-from-inventory or PO.

SRM provides you with inventory information along with the list of goods in the purchase request so that you can decide whether fulfilling the purchase request with a request-from-inventory or PO.

Prevent maverick spending

Maverick spending is created outside procurement policy, either by unauthorized persons or from non-preferred suppliers. It is an inefficient source of procurement that needs to be tackled. Minimizing maverick spending is one of the best procurement saving ideas you should take into account.

You can digitalize your procurement policies in

SRM and have it to reinforce conformance.

SRM and have it to reinforce conformance.

Regularly review suppliers

SRM helps you have regular performance reviews to evaluate your suppliers and to check their performance, whether they deliver products with satisfied quality and on schedule at a competitive cost, and grade them accordingly. Add new suppliers or remove suppliers that don’t meet up to your expectation, and gradually you will have a list of the highest grade suppliers that fit your requirements and optimize your spending.

SRM helps you have regular performance reviews to evaluate your suppliers and to check their performance, whether they deliver products with satisfied quality and on schedule at a competitive cost, and grade them accordingly. Add new suppliers or remove suppliers that don’t meet up to your expectation, and gradually you will have a list of the highest grade suppliers that fit your requirements and optimize your spending.

Provide self-service portals for suppliers

SRM provides the Supplier Portal to allow suppliers to manage their own accounts, view transactions, and communicate with your company. It saves time and money for unnecessary back-and-forth communication while ensuring deliveries meet requirements. This is a great way for your organization to reduce costs in supplier management, especially when you have a long list of suppliers.

SRM provides the Supplier Portal to allow suppliers to manage their own accounts, view transactions, and communicate with your company. It saves time and money for unnecessary back-and-forth communication while ensuring deliveries meet requirements. This is a great way for your organization to reduce costs in supplier management, especially when you have a long list of suppliers.

Utilize procurement KPIs

To help you spot improvement opportunities for your procurement,

SRM helps you set up clear procurement KPIs and monitor them closely. The tracking data will give you a better understanding of your procurement performance.

SRM helps you set up clear procurement KPIs and monitor them closely. The tracking data will give you a better understanding of your procurement performance.

Establish clear procurement policies

Establishing clear parameters for procurement and purchasing policies is crucial to reducing procurement costs. SRM offers you a comprehensive framework that will assure everyone can easily access and follow it. Thus, you can eliminate unnecessary purchasing, while enjoying a smoother supply chain process.

SRM offers you a comprehensive framework that will assure everyone can easily access and follow it. Thus, you can eliminate unnecessary purchasing, while enjoying a smoother supply chain process.

In addition,

SRM assists you in evaluating your procurement practices to see if they’re aligned with your budget and business strategy.

SRM assists you in evaluating your procurement practices to see if they’re aligned with your budget and business strategy.

Review your replacement strategies

How you plan to replace items can affect your bottom line. Routine replacement doesn’t apply to all components. For example, crucial machine parts should be replaced regularly to ensure the machine functions properly, while consumables can be replaced when necessary. In addition, remember to account for the cost and lead time of waiting for a replacement as well. You don’t want to disrupt your supply chain only to wait for a minor replacement.

SRM also helps you to track and evaluate your fixed assets regularly. Besides their book values,

SRM also helps you to track and evaluate your fixed assets regularly. Besides their book values,  SRM will keep all their repair and maintenance records to make it easier for you to make the decommissioning decisions.

SRM will keep all their repair and maintenance records to make it easier for you to make the decommissioning decisions.

Improve risk management

Procurement risk management helps you reduce or avoid risks to your business. Having a complete plan to foresee and tackle risks will better prepare you to handle unexpected events and avoid unplanned costs.

One of the most common risks facing organizations is supplier dependence. If a force majeure happens that makes the supplier unable to deliver goods on time, you should have a few alternative vendors on hand. Thus, make sure you don’t rely too much on a major supplier. Furthermore, pay attention to contract terms and follow up closely with vendors to prevent logistical issues.

SRM provides you with the supplier quota feature so that you can use it to avoid over dependence on a supplier.

SRM provides you with the supplier quota feature so that you can use it to avoid over dependence on a supplier.

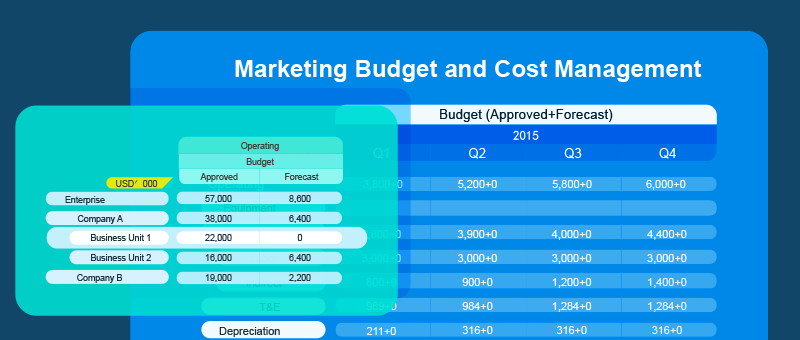

Collect and centralize data

Collecting accurate data is the first step to understanding your procurement performance. Then, connecting all data from procurement, inventory, and sales teams will give you a complete picture of critical metrics like inventory turnover ratio, inventory carrying cost, lead time, etc.

SRM can provide you with a centralized database that can give you insights on which items you should purchase more or less at which frequency, whether the inventory meets up the sales and whether you should change a supplier. It provides you with real-time reporting and guides you to find cost reduction techniques in procurement.

SRM can provide you with a centralized database that can give you insights on which items you should purchase more or less at which frequency, whether the inventory meets up the sales and whether you should change a supplier. It provides you with real-time reporting and guides you to find cost reduction techniques in procurement.

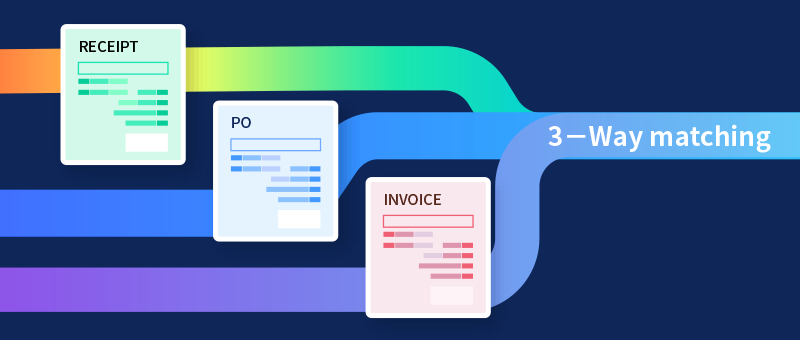

Automate the procurement process

Manual processing can slow down your process and add up to cost drastically. Automation of repetitive tasks can reduce labor costs and free your team to focus on more important things. Besides, you can avoid human mistakes in data entry and manual invoice processing, thus eliminating costly errors. SRM can offer you the adequate automation to cut down your manual processing costs.

SRM can offer you the adequate automation to cut down your manual processing costs.

Integrated systems and data

SRM provides you with a full blown supplier lifecycle management, sourcing & purchasing, warehouse & inventory and accounting & settlement integrated system. However, if you have other logistics systems or legacy systems that you must use,

SRM provides you with a full blown supplier lifecycle management, sourcing & purchasing, warehouse & inventory and accounting & settlement integrated system. However, if you have other logistics systems or legacy systems that you must use,  SRM provides External System Interfaces to allow you to integrate them and maintain straight-through-processing for your end-to-end workflows and your centralized database. The integration not only helps you cut down labor costs but also helps you avoid mistakes. Thus, the entire supply chain is complete and empowers you to manage all business activities with ease.

SRM provides External System Interfaces to allow you to integrate them and maintain straight-through-processing for your end-to-end workflows and your centralized database. The integration not only helps you cut down labor costs but also helps you avoid mistakes. Thus, the entire supply chain is complete and empowers you to manage all business activities with ease.

Train your staff and make savings a team effort

Procurement savings are not only about procurement, but also about teamwork. Educate your employees on the best procurement saving ideas to ensure everyone is on the same page. It involves a team effort to reduce spending, from sustainable procurement practices to business operations. Your team should adopt a mindset of purchasing cost savings and follow the best practices to optimize costs. You can digitalize your procurement policies in SRM and use

SRM and use  SRM to reinforce your team.

SRM to reinforce your team.