What is Purchase Order Management?

2024-11-06

Purchase order management is an important part of enterprise procurement activities. It controls and coordinates the generation, review, execution, and tracking of purchase orders through an effective management process to ensure the transparency and efficiency of the procurement process. In modern enterprise supply chain management, purchase order management is not only a process but also an important means to achieve cost control, risk management, and supply chain efficiency improvement. This article will discuss in detail the definition, importance, main processes of purchase order management, and the role of the purchase order management system in actual operations to help readers better understand and apply this management tool.

1. What is Purchase Order Management?

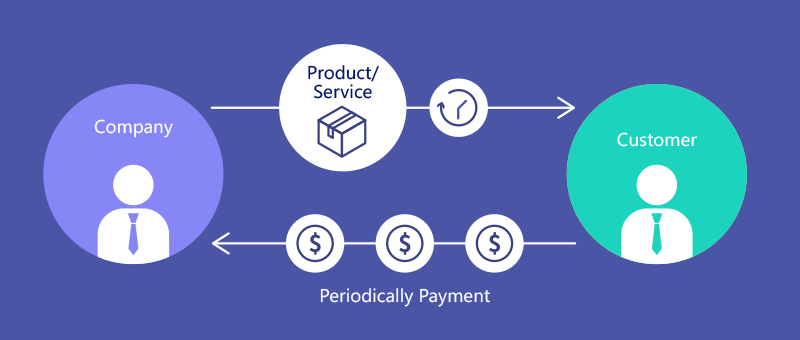

Purchase order management, usually abbreviated as POM , refers to the management work of creating, approving, executing, and tracking purchase orders in the enterprise procurement process. A purchase order is a formal document of the procurement agreement reached between the enterprise and the supplier, usually including information such as the name of the goods, quantity, price, and delivery date, and is the basis for contract performance. Effective purchase order management helps ensure the timely delivery of materials required by the enterprise, reduces procurement costs, and ensures that the procurement process meets quality standards and compliance requirements.

2.The Importance of Purchase Order Management

2.1 Ensuring Supply Chain Stability: Purchase order management is the key to ensuring the smooth operation of the supply chain. Through effective order management, enterprises can ensure the stable supply of key materials and products and avoid production delays caused by supply chain disruptions. Purchase order management can help enterprises accurately track the delivery progress of suppliers and quickly respond to any possible delays or problems, providing a guarantee for the business continuity of the enterprise.2.2 Improving Procurement Efficiency and Reducing Costs: Purchase order management can help enterprises handle orders more effectively, reduce redundant processes, and improve overall procurement efficiency. Through automated systems and process optimization, purchase order management can shorten the order processing time and thus improve efficiency. In addition, enterprises can avoid the cost increase caused by sudden procurement through reasonable procurement planning and order management, thus realizing reasonable cost control.

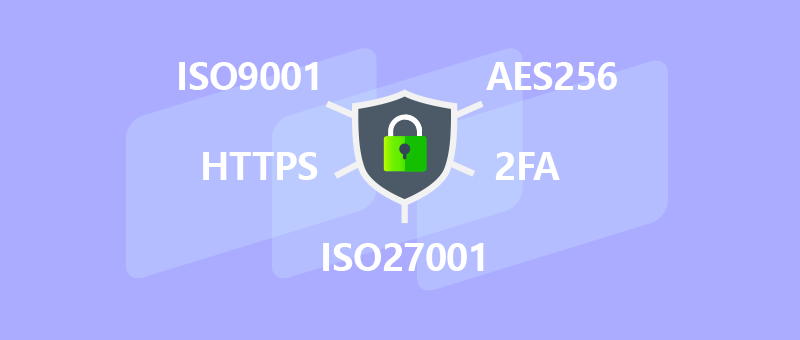

2.3 Enhancing Compliance and Reducing Risks: In the procurement process, compliance and risk control are key issues. The procurement management system can ensure that the approval process of each order is clear and avoid compliance problems caused by human factors. In addition, through the standardized purchase order management process, enterprises can better identify and control potential risks, thus reducing the financial or legal risks caused by order negligence.

3. The Process of Purchase Order Management

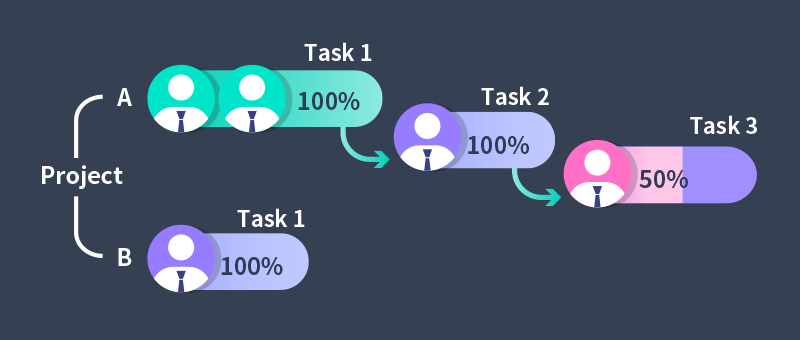

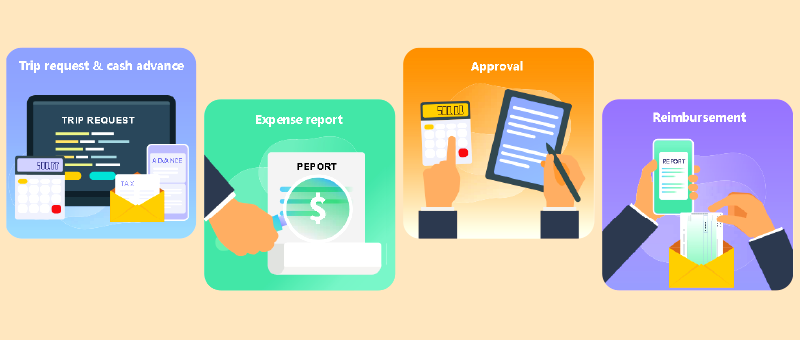

3.1 Requirement Confirmation and Order Creation: The first step in purchase order management is to clarify the material requirements of the enterprise and transform these requirements into orders. Requirement confirmation usually involves the cooperation of multiple departments to ensure the accuracy of the procurement requirements. After that, the procurement department will create a purchase order, listing the specific requirements of the required materials, including details such as quantity, specification, and delivery date. When creating an order, the system can automatically generate a standard format order to ensure the clarity and completeness of the information.

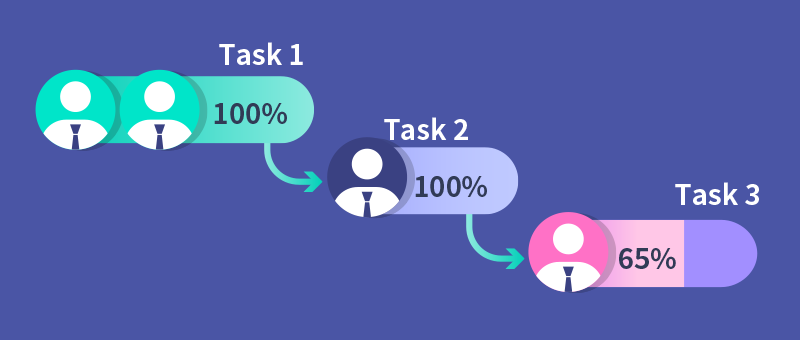

3.2 Order Approval: Before the purchase order is sent to the supplier, the enterprise usually needs to conduct an order approval process. This link ensures the rationality and compliance of the order and reduces invalid or unnecessary procurement behaviors. The order approval process can be multi-level, including the review and confirmation of various parties such as the department head, the financial department, and the compliance department. Through the approval process, the enterprise can effectively reduce the risks that may exist in the procurement process.

3.3 Order Execution and Tracking: Once the order is approved, the procurement department will send the order to the supplier, and the supplier will produce and deliver according to the order requirements. At this stage, the procurement department needs to track the execution of the supplier to ensure that the delivery time and quality meet the requirements. Real-time tracking of the order execution status can not only detect and solve problems in time but also help the enterprise adjust the subsequent procurement plan and improve the flexibility of the supply chain.

3.4 Acceptance and Payment: After the supplier delivers the goods, the procurement department will conduct acceptance of the goods, including checking the quantity and inspecting the quality. After the acceptance is qualified, the enterprise will make payment to the supplier according to the contract terms. This link is also the key to purchase order management. Through a compliant acceptance process, the subsequent risks caused by goods problems can be effectively avoided.

4. The Role of the Procurement Management System in Order Management

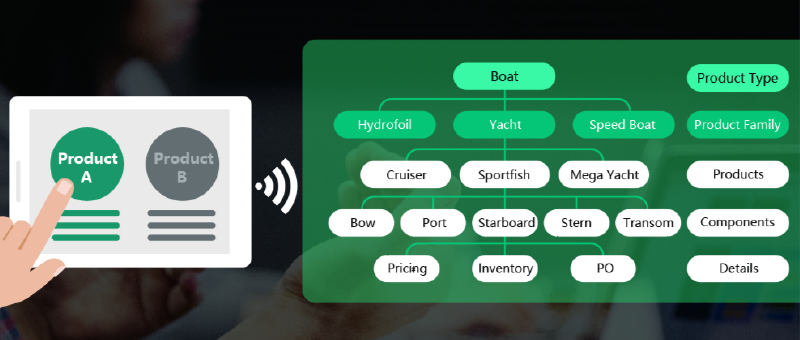

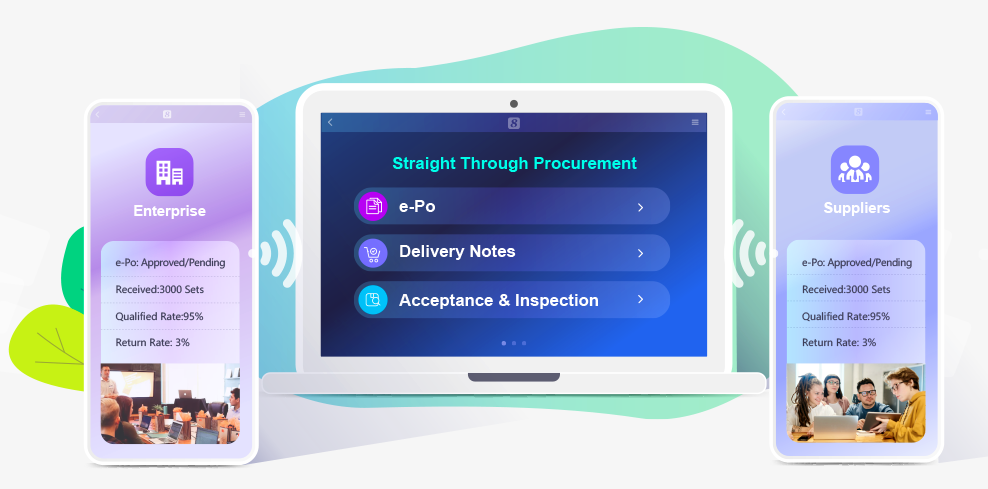

4.1 Automation and Digitalization of Processes: The procurement management system can automate the procurement process, greatly reducing manual operations and errors. The system can automatically generate orders, send approval requests, and track the execution of orders according to the requirements. This digital way not only improves procurement efficiency but also provides real-time data analysis for the enterprise to help it make better decisions and manage procurement.

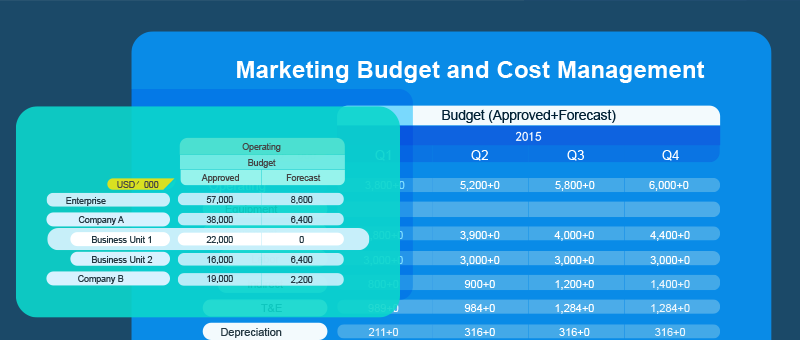

4.2 Centralized Management and Analysis of Data: Through the procurement management system, the enterprise can centrally store all order data for easy query and analysis. Centralized data management can help the enterprise identify trends and anomalies in procurement, optimize procurement strategies, and formulate reasonable inventory plans. Through system analysis, the enterprise can find opportunities for cost reduction and efficiency improvement and further improve supply chain management.

4.3 Improving Collaboration and Communication Efficiency: The procurement management system can integrate the information of different departments within the enterprise and suppliers on one platform, making the cooperation of all parties more smooth. The notification function of the system can update the order status in real time, so that all parties can timely know the progress and changes of the order. Efficient communication helps to quickly solve problems and improve the response speed and efficiency of the entire supply chain.

In summary, purchase order management plays an indispensable role in the modern enterprise supply chain. Effective purchase order management can not only help enterprises reduce procurement costs and improve efficiency but also enhance the stability of the supply chain and the quality of the supplier cooperation relationship. With the digital support of the procurement management system, enterprises will be able to better respond to market changes and achieve more efficient and compliant procurement processes. Teams that want to further improve the level of procurement management can use professional tools such as 8Manage SRM to assist in management. For more information, please visit the official website of 8Manage SRM: https://www.8manage.cn/srm_index.html

Related FAQs

1.What is the main purpose of purchase order management?

The main purpose of purchase order management is to ensure that the enterprises procurement process is efficient and transparent, and to control costs and reduce risks while ensuring the supply of materials. Through the management of purchase orders, enterprises can optimize the operation of the supply chain, ensure timely delivery, and improve the cooperative relationship with suppliers, thus better supporting the realization of business needs and goals.

2.How does the procurement management system help enterprises save costs?

The procurement management system significantly improves efficiency by simplifying and automating the order process, reducing manual operations and errors. The system can help enterprises formulate more cost-effective procurement plans through the analysis of historical order data. In addition, the real-time tracking function of the system can reduce the risk of emergency procurement and help enterprises avoid additional procurement costs.

3. How to choose a suitable procurement management system?

When choosing a procurement management system, enterprises should consider whether the functions of the system meet the business needs, including the degree of automation, data analysis ability, and integration with other systems. The ease of use of the system and the simplicity of the operation process are also key factors. In addition, enterprises should also consider the service quality and subsequent technical support of the supplier to ensure the continuous and effective operation of the system.

What is Procurement Contract Management?

What is Digital Project Management?