Special News

What is Supplier Management?

2024-10-21

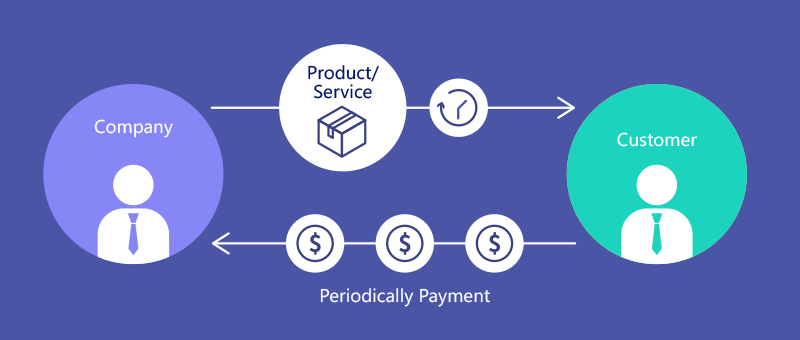

Supplier management is a core part of enterprise procurement and supply chain management. It involves the processes of selecting, evaluating, collaborating with, and supervising suppliers. Effective supplier management is not only for ensuring the smooth supply of products and services but also includes optimizing supplier relationships, reducing risks, controlling costs, and enhancing the overall competitiveness of the enterprise. In the context of intensified globalization competition, the importance of supplier management has become increasingly prominent, especially in different industries where procurement management has become one of the key business processes.

1. What is Supplier Management?

Supplier management refers to the process by which an enterprise establishes, develops, and maintains cooperative relationships with suppliers through a series of processes and tools to ensure the continuous supply of goods or services. This management process not only includes finding suitable suppliers but also involves how to ensure that the performance of suppliers meets the expectations of the enterprise through performance management. Effective supplier management can help enterprises reduce operating costs, improve procurement efficiency, and respond quickly in case of supply chain disruptions.

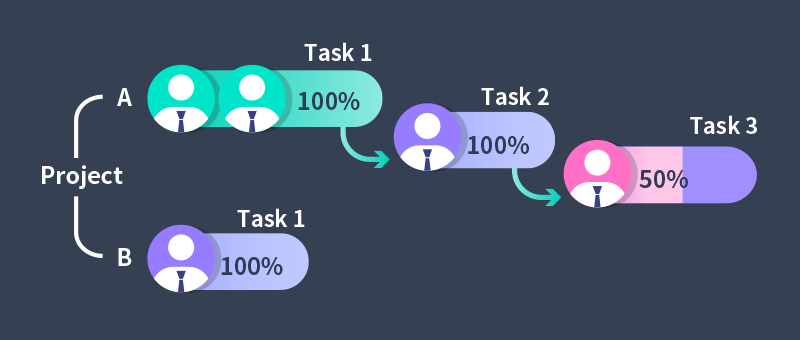

The process of supplier management usually includes the following stages: supplier selection, supplier performance evaluation, relationship maintenance and improvement, and contract management. Each stage requires close cooperation between the enterprise and the supplier to ensure the maximization of each others interests.

2. The Relationship between Supplier Management and Procurement Management

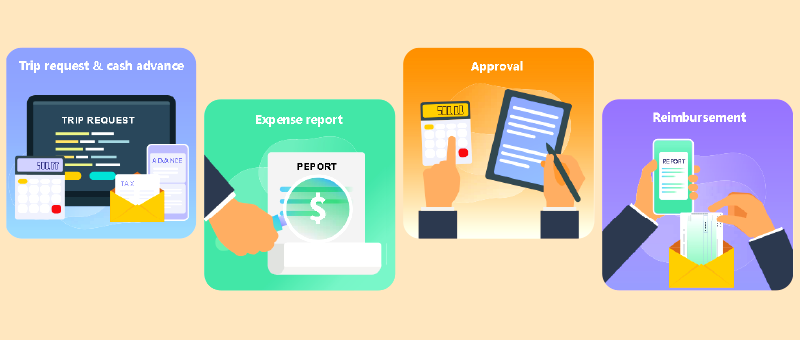

Procurement management is one of the core parts of supplier management, but the two are not completely equivalent. Procurement management mainly focuses on how to effectively procure materials or services, including from demand analysis, selecting suppliers, signing contracts to the actual delivery of materials. The scope of supplier management is broader. It not only includes the procurement process but also covers aspects such as establishing long-term cooperative relationships with suppliers, supplier risk management, and supplier performance monitoring.

Good supplier management can help enterprises gain more negotiation advantages in the procurement process, ensure better prices and service quality, and also enhance the flexibility and stability of the supply chain. In modern enterprise operations, procurement management increasingly needs to be combined with supplier management to achieve comprehensive optimization of the supply chain.

3. The Main Steps of Supplier Management

(1) Supplier Screening and Evaluation

The first step in supplier management is to screen and evaluate potential suppliers. This process needs to consider multiple factors, including the quality, price, delivery capacity, service level, and financial status of the suppliers. For an enterprise, choosing the right suppliers is the key to ensuring the smooth operation of the supply chain.

To make a wise choice, an enterprise usually conducts background investigations and on-site inspections of suppliers and evaluates them in multiple ways, such as quality audits, financial analysis, and market reputation. Through these evaluations, an enterprise can find suppliers who can cooperate for a long time and have a competitive advantage.

(2) Supplier Performance Management

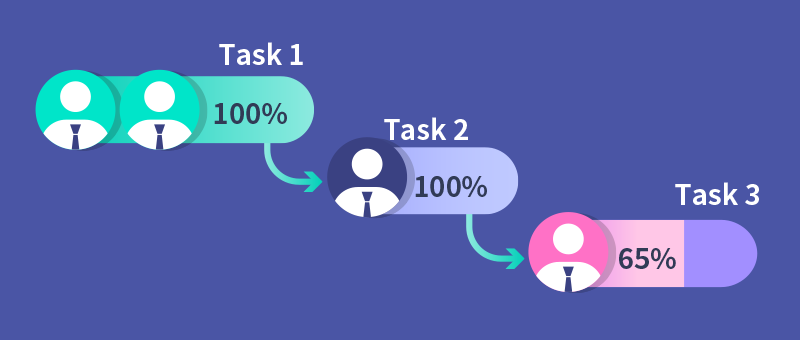

Once a supplier is selected, an enterprise needs to conduct continuous performance management on it. This includes regularly monitoring the performance of the supplier to ensure that they can deliver products or services on time and that the quality meets the standards. If a supplier performs poorly, an enterprise should take timely measures, either adjust the cooperation method or even replace the supplier.

Performance management is usually carried out through a set of clear indicators, such as delivery time, quality rate of compliance, customer satisfaction, etc. Regular performance evaluations not only help to discover potential problems in the supply chain but also help suppliers to continuously improve and enhance the cooperation efficiency of both parties.

(3) Supplier Relationship Management

The purpose of supplier relationship management is to enhance the mutual trust and cooperation level between both parties through strengthening communication and cooperation. This not only includes communication during contract performance but also involves strategic cooperation between the supplier and the enterprise. For example, in the face of market demand fluctuations or supply chain disruptions, a good supplier relationship can help an enterprise quickly adjust the supply plan and reduce losses.

A long-term stable supplier relationship can also prompt both parties to jointly innovate and develop new products and services, thus achieving a win-win situation. This cooperation relationship is based on mutual understanding and common interests and requires continuous communication, negotiation, and adjustment between the enterprise and the supplier.

(4) Supplier Risk Management

An inescapable part of supplier management is supplier risk management. When an enterprise selects a supplier, it not only needs to consider its short-term capabilities but also needs to pay attention to potential risks in long-term cooperation, such as financial instability, geopolitical risks, and natural disasters. Effective risk management can help an enterprise reduce the possibility of supply chain disruptions and have sufficient response plans when a supplier has problems.

An enterprise can reduce risks by dispersing suppliers, establishing backup supply chains, and regularly evaluating supplier risks. In this way, even if a certain supplier has a problem, an enterprise can quickly find an alternative solution to ensure that production and operation are not significantly affected.

4. The Challenges of Supplier Management

(1) The Diversity and Complexity of Suppliers

With the development of globalization, an enterprises suppliers may come from different countries and regions. Although this diversity provides more options for the enterprise, it also increases the management complexity. Suppliers in different regions are subject to different laws and regulations, cultural backgrounds, and market environments, which makes it difficult to implement a unified supplier management standard.

(2) The Stability and Quality Control of Suppliers

In some industries, the stability of suppliers directly affects the production and operation of an enterprise. Once the delivery capacity or quality of a supplier appears to be a problem, an enterprise may face serious production delays and customer complaints. Therefore, how to ensure the stability of suppliers and continuously provide high-quality products or services is one of the difficulties in supplier management.

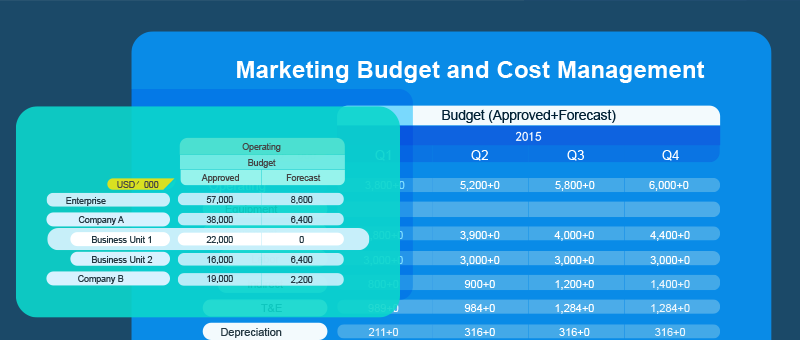

(3) The Cost Management of Suppliers

Cost is one of the main factors that an enterprise pays attention to when selecting a supplier. However, a low-cost supplier is not necessarily the best choice. While pursuing low cost, an enterprise also needs to balance quality, delivery time, and service. Excessive pursuit of low price may lead to quality problems or supply chain instability, thus bringing higher hidden costs to the enterprise.

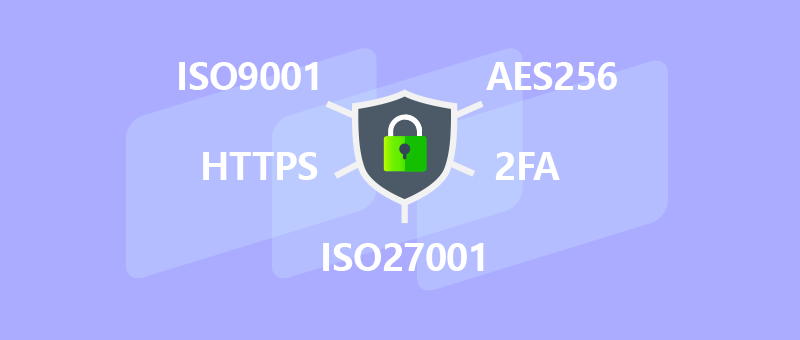

(4) The Influence of Technology and Digital Transformation

With the development of technology, supplier management is gradually transforming towards digitalization and automation. An enterprise can improve the efficiency of supplier management through technical means such as 8Manage SRM supplier management software and e - procurement systems. However, digital transformation also brings new challenges, including how to adapt to the rapid changes of technology and how to protect the supply chain data security.

5. The Future Trends of Supplier Management

(1) Digitalization and Automation

With the development of big data, the Internet of Things, and artificial intelligence, supplier management will be more digital and intelligent. An enterprise will be able to monitor every link of the supply chain in real time, automatically identify the risks of suppliers, and make rapid adjustments. This not only can improve management efficiency but also can significantly reduce errors and delays in manual operations.

(2) Sustainability and Social Responsibility

In the future, supplier management will increasingly focus on sustainable development and social responsibility. An enterprise will require suppliers to comply with environmental standards and protect employee rights during production. This is not only to meet the needs of consumers but also to respond to increasingly strict government regulations and market supervision.

(3) The Global Supply Chain Reshaping

With the change of geopolitical situation and the influence of uncontrollable factors such as the epidemic, an enterprise is reevaluating the layout of its global supply chain. In the future, an enterprise may be more inclined to localize or regionalize suppliers to reduce the risk of global supply chain interruptions. This trend will prompt supplier management to develop in a more flexible and dispersed direction.

6. Related Questions and Answers (FAQs)

(1) What is a Supplier Management System?

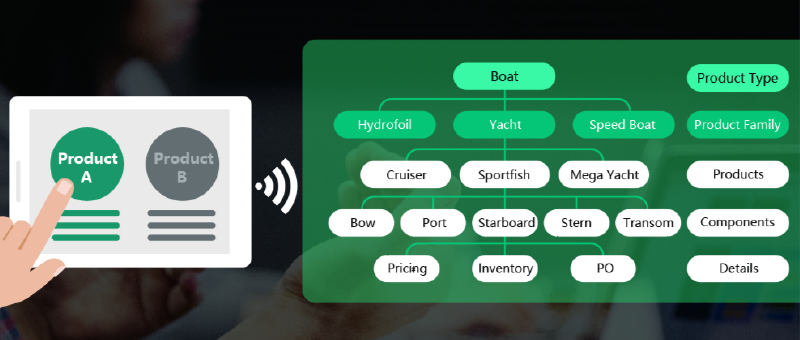

A Supplier Management System is software used to manage the relationship between an enterprise and its suppliers. Its main functions include supplier information management, evaluation and screening, procurement process management, contract management, performance monitoring, and communication and cooperation. It can record the basic information and qualification documents of suppliers, set evaluation indicators to screen high - quality suppliers,collaboratively manage the procurement process and contract, monitor performance and provide a communication platform. Its importance lies in improving procurement efficiency, reducing costs, ensuring supply quality, enhancing supply chain stability, and enhancing the competitiveness of the enterprise, which is of crucial significance for the enterprise to achieve efficient operation and sustainable development.

(2) Why is Supplier Relationship Management so important?

Supplier Relationship Management helps an enterprise establish a long - term mutually beneficial cooperation relationship with its suppliers. Through good communication and cooperation, an enterprise can enhance the stability and flexibility of the supply chain. When the market demand fluctuates or the supply chain has a problem, a strong supplier relationship can help an enterprise quickly adjust and avoid supply interruptions. In addition, a long - term cooperation relationship can also promote the joint innovation of suppliers and the enterprise and provide higher quality products and services.

(3) How to effectively conduct Supplier Performance Evaluation?

Supplier Performance Evaluation is usually based on a series of key performance indicators (KPIs), such as delivery time, quality rate of compliance, service response speed, etc. An enterprise needs to regularly collect and analyze these data to evaluate the performance of a supplier. To ensure the objectivity and comprehensiveness of the evaluation, an enterprise can combine internal data and customer feedback to understand the true performance of a supplier. If the performance of a supplier does not meet the expected, an enterprise should communicate with it, offer improvement suggestions or reevaluate the cooperation relationship.

Conclusion

Supplier management is an important part of enterprise supply chain management. Good supplier management can not only improve procurement efficiency, reduce operating costs, but also help an enterprise establish a more flexible and stable supply chain system. With the progress of technology and the continuous change of the global supply chain, the digitalization and intelligence trends of supplier management will continue to accelerate. For teams that want to further improve their supplier management level, they can use professional software such as 8Manage SRM for assistance. 8Manage SRM website: https://www.8manage.cn/srm_index.html

Most popular

How IPD drives product R&D toward commercial success

Top procurement management systems to elevate your business in 2025

Are your project managers ready for AI?

Related articles

Top 5 procurement management software tools to boost business efficiency

2025-04-11

Which procuarement management software is best? A review of 10 leading options

2025-04-03

SRM procurement systems: Boost efficiency, competitiveness with 6 top tools

2025-03-24

How to choose the best procurement management software for your business?

2025-03-07

Top 5 procurement and tender management systems in 2025: Rankings and reviews

2025-03-05

Previous Article >

What is R&D Project Management?

What is R&D Project Management?

Next Article >

What is Project Management?

What is Project Management?