What is Procurement Management?

2024-10-17

Procurement management encompasses more than just purchasing materials; it also involves selecting suppliers, contract management, logistics coordination, and quality control. The core objective of procurement management is to minimize costs while ensuring quality and avoiding supply chain disruptions. As companies grow and the market environment becomes more complex, effective procurement management plays a crucial role in enhancing a companys competitiveness.

1. Definition of Procurement Management

Procurement management refers to the process by which a company formulates and executes procurement strategies to acquire the necessary resources from the supply market. This process covers all stages from identifying needs, selecting suppliers, to contract execution and payment settlements. Procurement management not only aims to optimize pricing but also focuses on timely delivery, service quality, and the long-term partnership potential with suppliers. It also plays a coordinating role within a company’s operations, ensuring that all departments receive the resources they need in a timely and appropriate manner.

2. Importance of Procurement Management

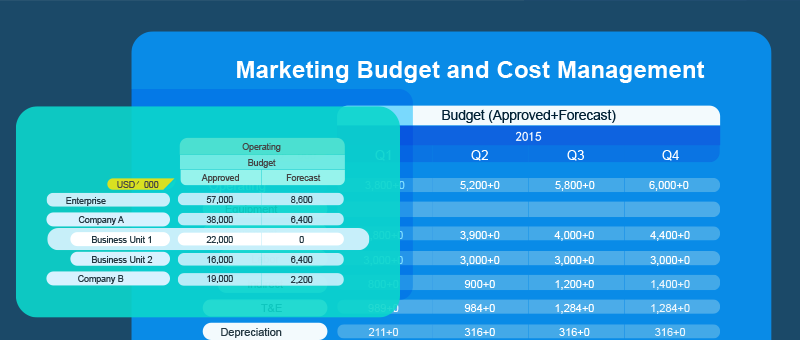

1. Cost Control and Savings

Procurement management is a key method for companies to control costs. By negotiating better prices with suppliers, companies can significantly reduce operational expenses. Moreover, centralized procurement and economies of scale allow companies to secure larger discounts through bulk purchases. Effective procurement management can also reduce redundant purchases and excess inventory, preventing resource waste. Over time, these cost-saving measures will lead to higher profits and greater market competitiveness for the company.

2. Ensuring Supply Chain Stability

A stable supply chain is the foundation of a company’s smooth production and service operations. Through a well-established network of suppliers, procurement management ensures a steady supply of raw materials and goods. Procurement teams must also stay updated on suppliers’ production capacity and logistics to identify potential risks early on. For critical materials, companies often work with multiple suppliers to minimize supply risks and ensure supply chain flexibility.

3. Improving Product Quality

The quality of a product largely depends on the quality of the raw materials and components procured. Through rigorous supplier evaluations and quality control, companies can prevent defective products from entering their production processes. Close collaboration between the procurement and quality inspection teams ensures that each batch of materials meets company standards. High-quality procurement reduces defects, enhances customer satisfaction, and improves the company’s brand image.

4. Risk Management

In procurement, companies must not only monitor market price fluctuations but also guard against risks like supplier defaults and logistical delays. By establishing detailed contract terms, companies can transfer or distribute risks. Additionally, contingency plans should be in place, such as maintaining safety stock and adopting multi-supplier strategies to deal with unforeseen events. Effective risk management enables companies to navigate market uncertainties more confidently.

5. Enhancing Competitiveness

Optimized procurement processes can increase a company’s responsiveness to market demands, providing timely support for product development and production. By establishing long-term partnerships with suppliers, companies can gain technical support and market insights, further enhancing their competitive edge. Efficient procurement management also supports sustainable development, such as by selecting environmentally-friendly suppliers and optimizing energy use. In summary, effective procurement management will provide companies with more opportunities in a competitive market.

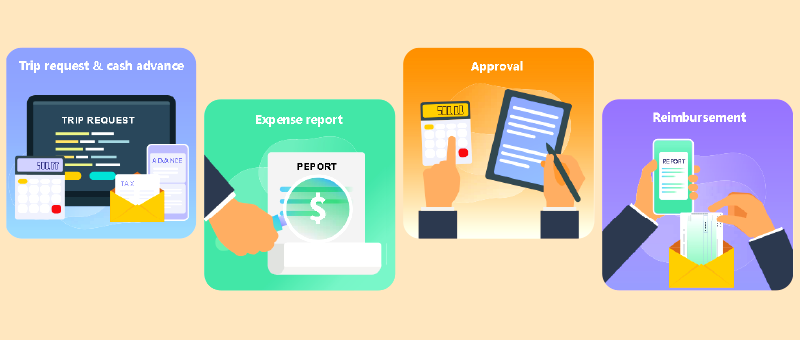

3. Main Processes in Procurement Management

1. Identifying Needs

The first step in the procurement process is accurately identifying the company’s procurement needs. These needs are typically proposed by production, research and development, or sales departments and include the type of materials, specifications, quantities, and delivery timelines. Companies must carefully analyze market demand and internal inventory to avoid excess procurement that leads to stockpile issues. A well-defined needs identification process can reduce the frequency of last-minute purchases, improving the precision and efficiency of procurement planning.

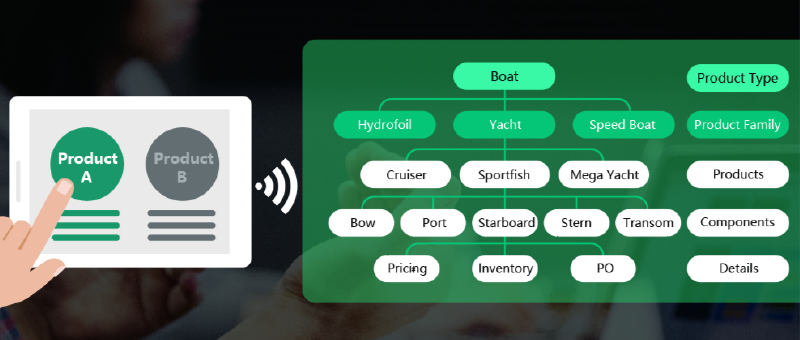

2. Supplier Selection and Evaluation

Selecting suppliers is crucial to procurement management. Companies must evaluate suppliers based on several criteria such as qualifications, reputation, delivery capabilities, quality standards, and pricing. Beyond pricing, factors like production capacity and response speed are also key considerations. Companies can conduct on-site inspections or review past cooperation records to better understand a suppliers situation. Regularly evaluating supplier performance helps optimize the supply chain and ensures stable long-term cooperation.

3. Quotations and Tendering

Once the supplier list is confirmed, companies can obtain quotations through public tenders or inquiries. Open tenders ensure transparency in the procurement process and allow for comparing bids from multiple suppliers. During this stage, companies should also consider factors like technical support, service quality, and after-sales services. A well-structured tendering process will help companies choose the best partners, achieving a balance between cost and quality.

4. Price Negotiation and Contract Signing

Price negotiations affect not only direct costs but also the procurement cycle and other conditions. Companies should communicate thoroughly with suppliers on payment terms, delivery timelines, after-sales services, and other clauses. During negotiations, procurement departments must balance short-term gains with long-term relationships to create a win-win partnership. The final contract should clearly outline both parties rights and obligations, minimizing potential disputes during the cooperation.

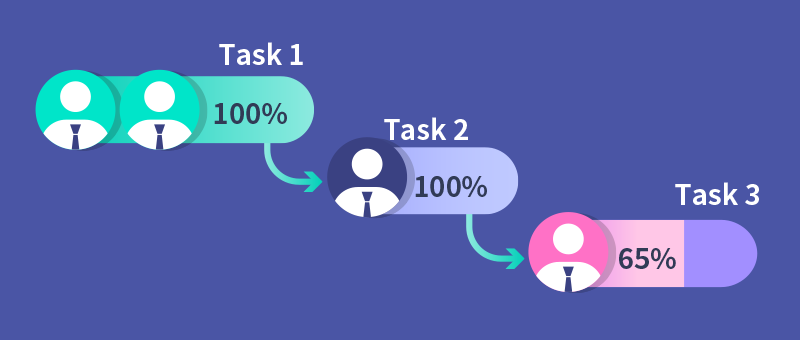

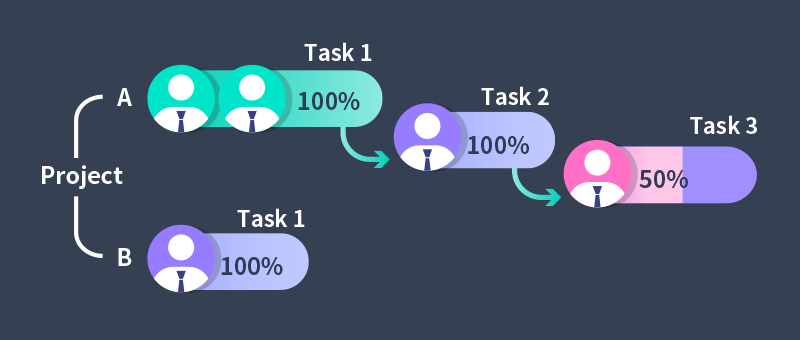

5. Order Execution and Tracking

After contract signing, the procurement department must issue purchase orders and track the supplier’s progress. Companies can use procurement management systems to monitor order status in real-time, ensuring timely deliveries. If any delivery issues arise, the procurement team should promptly communicate with the supplier to resolve them, preventing production delays. Proper order tracking is essential for the smooth implementation of procurement plans.

6. Inspection and Quality Control

Once suppliers deliver the goods, the company must conduct quality inspections, including appearance checks, specification verifications, and necessary performance testing. For any non-conforming materials, the company should promptly communicate with the supplier to arrange returns or replacements. Strict inspection procedures not only ensure the quality of procured materials but also raise suppliers’ awareness of quality standards.

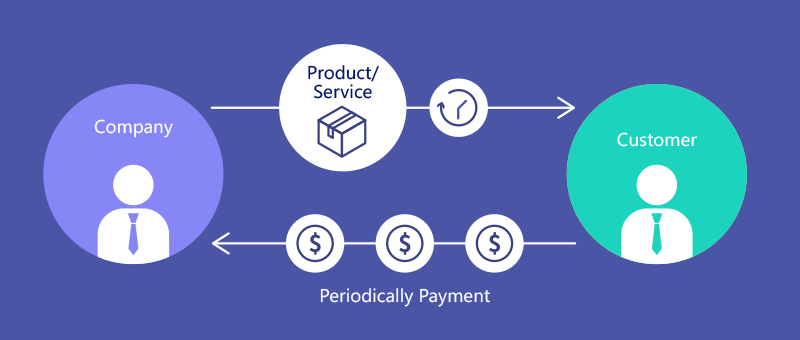

After goods pass inspection, companies must make payments according to the contract terms. Payment methods can include prepayments, installments, or payment on delivery, depending on the company’s cash flow situation. Procurement departments must work closely with the finance department to ensure clear accounts and avoid payment delays. Timely payment is not only a sign of good faith but also helps secure better collaboration opportunities and favorable terms from suppliers.

8. Supplier Relationship Management

Strong supplier relationships are key to successful procurement management. Companies should maintain regular communication, performance reviews, and feedback to build trust with suppliers. Effective supplier relationship management enhances supply chain stability and fosters collaboration on technological innovation and market expansion. In the long term, stable partnerships will give companies a competitive advantage.

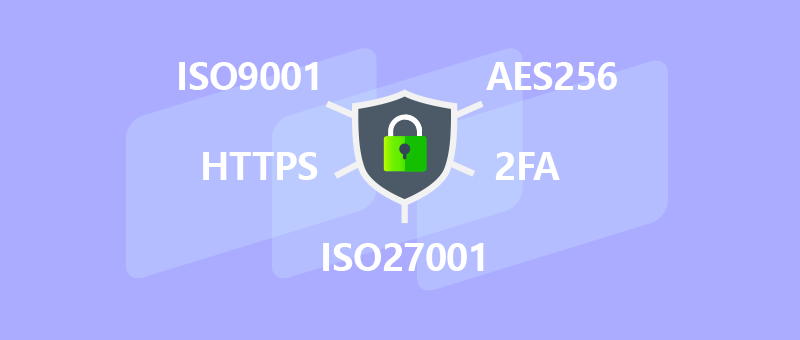

In summary, procurement management is an important pillar of enterprise operation, which not only reduces procurement costs but also ensures the efficient operation of the supply chain and effective risk control. Through scientific procurement management, enterprises can enhance their competitiveness in complex market environments and achieve sustainable development. In the future, with the popularization of digital technology, procurement management will become more intelligent and transparent, creating more value for enterprises. For teams that want to further improve their procurement management level, professional tools such as 8Mnage SRM can be used for assistance. 8Mnage SRM official website: https://www.8manage.cn/srm_index.html

4、 Related Q&A FAQs

What is the difference between procurement management and supply chain management?

Procurement management focuses on the entire process of obtaining materials and services from external markets for enterprises, mainly involving supplier selection, price negotiation, and order execution. The scope of supply chain management is broader, covering the entire process from raw material procurement, production, warehousing to final product delivery. Procurement management is a part of supply chain management, and the efficient collaboration between the two can ensure the normal operation of enterprises.

How to choose the appropriate procurement strategy?

Enterprises should develop flexible procurement strategies based on business needs and market dynamics. For example, for important core materials, it is recommended to adopt a long-term cooperation model to ensure stable supply; For non core materials, short-term contracts or market procurement can be used to reduce inventory risks. Enterprises also need to comprehensively consider procurement volume, budget, and supplier capabilities to choose the optimal procurement plan.

How to avoid supplier delivery delays?

Enterprises should specify delivery time and breach clauses in contracts to reduce the possibility of delivery delays. In addition, a multi supplier strategy and safety stock mechanism can be adopted to enhance emergency response capabilities. In practical operation, the procurement department should maintain close communication with suppliers, timely grasp the production and logistics situation, so as to take measures before problems occur.

What is Project Management?