2025 Guide to supplier management systems for manufacturers

2025-01-24

The manufacturing industry is undergoing seismic changes. Fluctuating raw material costs, frequent supply chain disruptions, and increasingly personalized customer demands have rendered traditional supplier management methods obsolete. The outdated "price game" approach no longer suffices in today’s dynamic market. Instead, manufacturers must foster closer, collaborative supplier relationships, moving toward a "value co-creation" partnership model.

To successfully navigate this transition, an efficient supplier management system is indispensable. This article explores five supplier management systems that are ideal for manufacturing companies, providing insights into their features, advantages, and limitations. With the right system, manufacturers can build a resilient, agile, and sustainable supply chain, gaining a competitive edge in 2025 and beyond.

Why supplier management systems are critical for manufacturing

The manufacturing sector relies heavily on suppliers for raw materials, components, and services. Any inefficiency or disruption in the supply chain can lead to production delays, increased costs, and lost revenue. Here’s why investing in a robust supplier management system is essential:

- Streamlined supplier selection: Identify and onboard reliable suppliers quickly.

- Enhanced collaboration: Foster real-time communication and collaboration with suppliers.

- Risk mitigation: Monitor and mitigate risks such as supplier defaults or geopolitical disruptions.

- Cost optimization: Automate procurement processes to reduce costs and improve efficiency.

- Data-driven decisions: Leverage analytics to make informed decisions and improve supplier performance.

Now, let’s dive into the top five supplier management systems for manufacturing companies.

Manufacturing supplier management: Top picks for 2025

1. 8Manage SRM

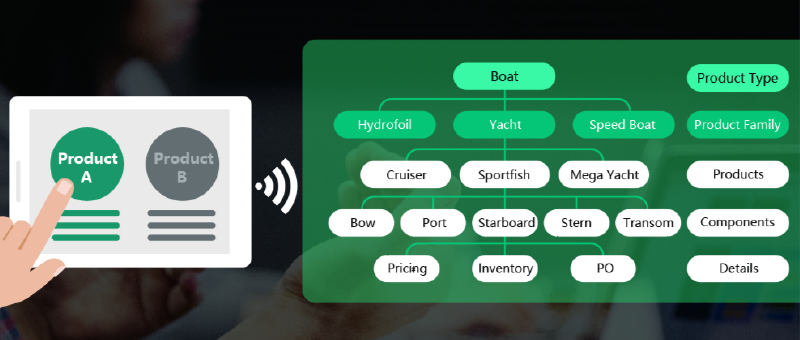

8Manage SRM is a digital procurement collaboration platform designed to streamline supplier interactions. It covers the entire supplier lifecycle, from selection and evaluation to contract management and performance tracking.

Key features

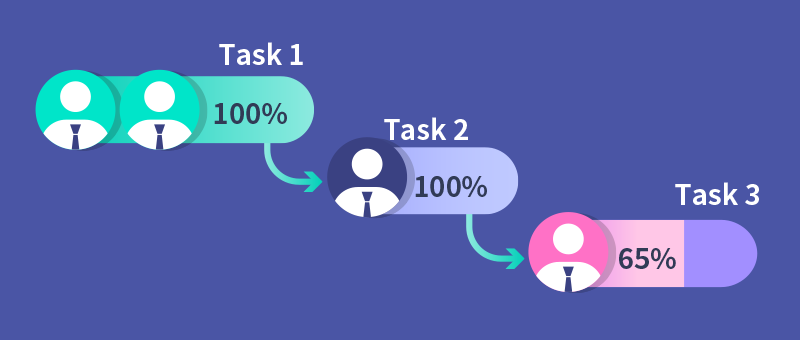

- Supplier lifecycle management: Stringent supplier onboarding processes, custom assessment models, periodic performance reviews, and issue tracking.

- Procurement collaboration: Initiate inquiries in batches online, with suppliers receiving notifications and submitting quotes. The system generates automated price comparisons.

- Bidding collaboration: Fully transparent, real-time online collaboration for bids, enhancing efficiency and accountability.

- Contract management: Comprehensive tracking of procurement, stocking, and service contracts.

Advantages

- End-to-end visibility: Tracks supplier performance and collaboration in real time.

- Automation: Reduces manual effort in procurement and contract management.

- Scalability: Suitable for businesses of all sizes.

Best for

Manufacturers looking for a cost-effective, user-friendly solution to manage supplier relationships and optimize procurement processes.

2. Coupa supplier management

Coupa is a cloud-based business spend management (BSM) platform that focuses on optimizing supplier relationships and enhancing procurement efficiency.

Key features

- Supplier information management: Centralizes supplier data for easy access and analysis.

- Procurement automation: Streamlines purchase orders, approvals, and invoice management.

- Risk assessment: Identifies and mitigates supplier risks proactively.

Advantages

- Comprehensive spend management: Covers procurement, contracts, and supplier performance.

- AI-powered insights: Provides actionable data to improve decision-making.

- User-friendly interface: Easy to implement and use.

Limitations

- High cost: May be expensive for small and medium-sized enterprises (SMEs).

- Customization challenges: Requires additional effort for industry-specific needs.

Best for

Large manufacturers seeking a comprehensive, AI-driven solution for spend management and supplier collaboration.

3. SAP Ariba

SAP Ariba is a global leader in procurement and supplier management, offering end-to-end solutions for supply chain optimization.

Key features

- Supplier collaboration: Enables real-time communication and collaboration with suppliers.

- Spend analysis: Provides insights into global spending patterns and supplier performance.

- Contract and catalog management: Simplifies contract creation and e-procurement.

Advantages

- Global reach: Ideal for multinational manufacturers.

- Integration: Seamlessly integrates with SAP ERP and other enterprise systems.

- Scalability: Handles complex supply chains with ease.

Limitations

- Complex implementation: Requires significant time and resources.

- High costs: Licensing and maintenance can be expensive.

Best for

Large enterprises with complex, global supply chains that need a robust, scalable solution.

4. Oracle supplier management

Oracle’s supplier management system is a comprehensive solution for managing supplier interactions and optimizing procurement processes.

Key features

- Supplier information Management: Centralizes supplier data for easy access.

- Procurement automation: Streamlines purchase orders, approvals, and inventory management.

- Quality and risk management: Ensures compliance and mitigates risks.

Advantages

- Integration: Works seamlessly with Oracle ERP and SCM systems.

- Customization: Highly adaptable to specific business needs.

- Analytics: Provides deep insights into supplier performance and costs.

Limitations

- High costs: Licensing and implementation can be prohibitive for SMEs.

- Complexity: Requires skilled personnel for setup and maintenance.

Best for

Large manufacturers with existing Oracle ecosystems looking for a highly integrated solution.

5. IBM emptoris supplier management

IBM Emptoris is a powerful supplier management system designed to optimize supplier relationships and enhance procurement efficiency.

Key features

- Supplier lifecycle management: Tracks supplier performance and compliance.

- Procurement automation: Streamlines sourcing, contracting, and procurement processes.

- Risk management: Monitors and mitigates supply chain risks.

Advantages

- AI and analytics: Leverages IBM’s AI capabilities for predictive insights.

- Integration: Works well with IBM Watson and other enterprise systems.

- Flexibility: Customizable to meet specific industry needs.

Limitations

- High Costs: May be expensive for smaller manufacturers.

- Implementation Complexity: Requires significant time and expertise.

Best for

Large manufacturers seeking an AI-powered, highly customizable solution for supplier management.

How to choose the right supplier management system

Manufacturing companies must carefully evaluate their specific needs, scalability requirements, and budget constraints when selecting a supplier management system. Key factors to consider include:

- Integration capabilities with existing ERP systems.

- Automation and analytics features for improved efficiency.

- Scalability to adapt to future business growth.

By implementing the right supplier management system, manufacturing companies can build resilient supply chains, enhance collaboration, and secure long-term competitiveness.

Conclusion

In the fast-paced world of manufacturing, efficient supplier management is no longer optional—it’s a necessity. The right supplier management system can help you build stronger supplier relationships, reduce costs, and mitigate risks, giving you a competitive edge in 2025 and beyond.

Whether you choose 8Manage SRM for its affordability, Coupa for its AI-driven insights, SAP Ariba for its global reach, Oracle for its integration capabilities, or IBM Emptoris for its advanced analytics, each system offers unique benefits tailored to different manufacturing needs.

Investing in a robust supplier management system is not just about improving efficiency—it’s about future-proofing your supply chain and ensuring long-term success in an increasingly competitive market.

2025 Best team project management software: Top picks by category